5

A

B

10

c

m

ENGLISH

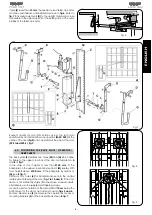

If gap

(S)

is less than

15 mm

, the special curved telescopic arms

must be used instead, and installed as shown in

fig.6

. Refer to

fig.7

to fix square elements

(D)

to the upright member as close

as possible to the upper support of the existing arm. Fit the outer

profiles of the telescopic arms.

Fig. 6

Fig.7

Respect maximum door dimensions as per the technical

specifications and install either one operator

(FAAC 595)

at the

centre of the door

(fig.8)

or two operators at the sides of the door

(595 I and 595 S)

,

fig.9.

Fig. 9

Fig. 8

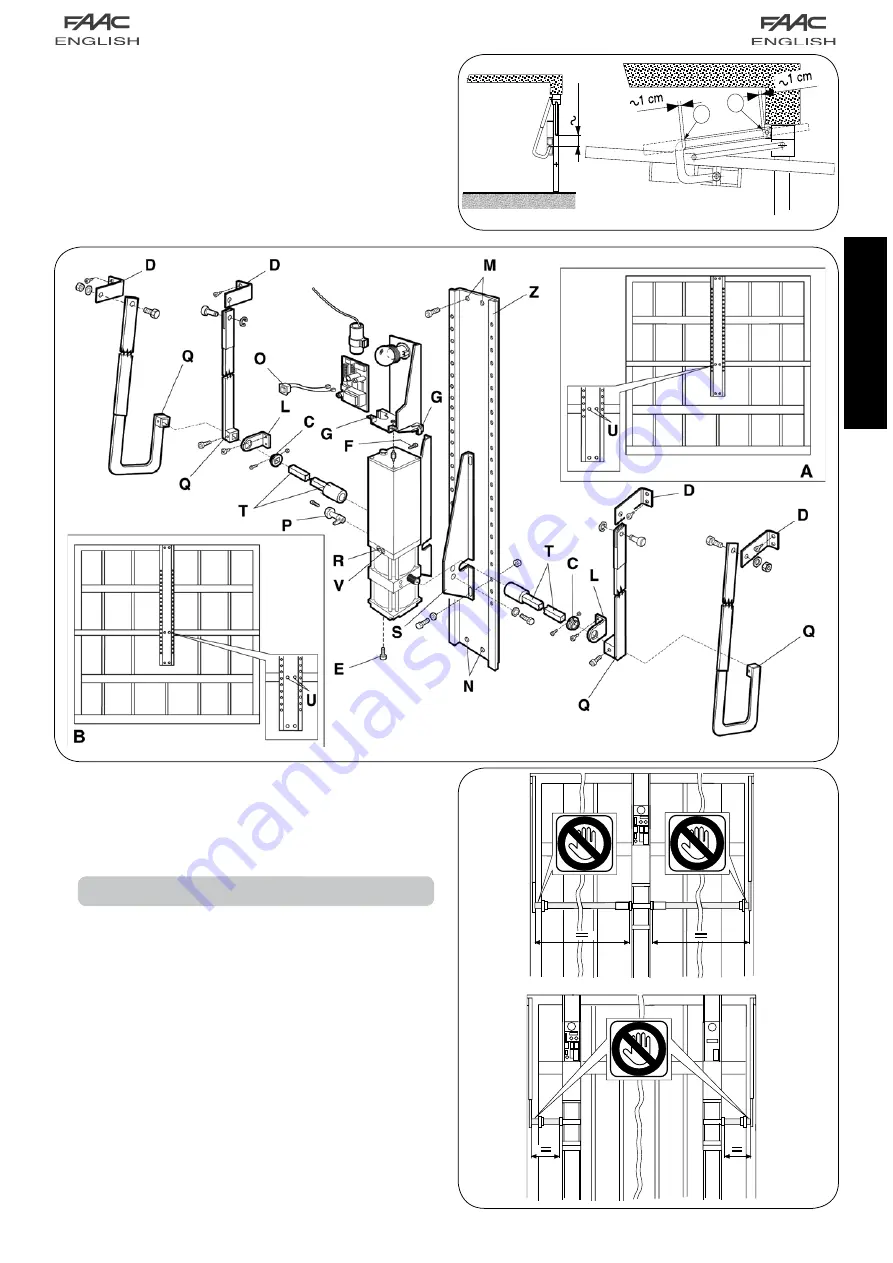

4.4. POSITIONING THE BACK PLATE / OPERATOR /

DRIVE SHAFTS

The back plate

(Z)

features two holes

(M)

and

(N)

which allow

for fixture to the upper cross bar of the door as indicated in

A

and

B

of

fig.7

.

In the case of door heights of less than

2100 mm

, fit the

backplate on the upper cross bar by means of

(M)

(see

A

). With

door heights above

2100 mm

, fit the backplate by means of

(N)

(see

B

,

fig.7

).

Drill two 6 mm holes

(U)

for backplate fixture onto the central

reinforcement ribbing of the door (

fig.7 ref. A and B

). If the door

frame is not sufficiently sturdy (thin sheet) use screwed inserts.

Alternatively, use the supplied self-tapping screws.

Locate the point of rotation of the drive shaft at

10 cm

below the

bottom pivot of the door’s own arm as shown in

figs. 5 and 6

.

Remove bleed screw

(F)

and secure the operator by means of

mounting brackets

(S)

on the backplate as shown

in fig.7.

Summary of Contents for 595

Page 1: ...595...