| English

12

the “I” position.

6.

Let it run until antifreeze comes out through

the lance.

7.

Suck up antifreeze with the detergent intake

system too.

8.

Disconnect the machine from the mains elec

-

tricity supply.

NOTE

Anti-freeze may cause environmental pollution. Al

-

ways follow the instructions given on the pack.

MAINTENANCE AND CLEANING

WARNING

Disconnect the machine from the mains electricity

supply and close the water supply tap before carry-

ing out any maintenance jobs. Once maintenance has

been completed, ensure that the closing panels have

been correctly reassembled and anchored with the

screws provided before reconnecting the machine

to the mains.

MAINTENANCE SCHEDULE

Items

B

ef

o

re e

ac

h u

se

Ev

er

y 5

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 1

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 2

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 3

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 5

0

0

hr

s o

f o

p

er

at

io

n

Complete

unit

Visual

Ispection

√

Control

handles

Check

√

Power

cables

Check

√*

Pipes

Check

√*

High

pressure

connec-

tions

Check

√*

Fuel fiter

Check -

Clean

√*

Water filter

Check -

Clean

√

Fuel tank

Clean

√

Boiler coil

Clean

√**

Descale

√**

Pump oil

and seals

Change

√**

Fuel pump

Clean

√**

Fuel nozle

Change

√**

Electrodes

Regulate

√**

Change

√**

Frequency

Items

B

ef

o

re e

ac

h u

se

Ev

er

y 5

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 1

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 2

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 3

0

0

hr

s o

f o

p

er

at

io

n

Ev

er

y 5

0

0

hr

s o

f o

p

er

at

io

n

Safety

devices

Check

√

Calibrate

√**

Lance

nozzle

Change

√

*These items should be replaced if needed.

**These components should be serviced and repaired only

by authorized service center, that have the proper tools and

expertise.

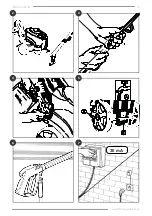

POWER CORD

To avoid shock or fire hazard, if the power cord is

worm or cut, or damaged in any way, have it re

-

place immediately.

Electrical connection cables often suffer insula

-

tion damage. Possible causes are:

1. Punch points when connection cables are run

through window or door gaps.

2.

Kinks resulting from incorrect attachment or

laying of the connection cable.

3.

Cuts resulting from running over the connect

-

ing cable.

4.

Insulation damage resulting from forcefully

pulling out of the wall socket.

5. Cracks through aging of insulation.

Such defective electrical connection cables must

not be used as the insulation damage makes them

extremely hazardous.

FUEL FILTER

Remove and replace the inline fuel filter (Fig. 14)

from time to time.

WATER FILTER

Clean the water intake filter regularly and free it

from any impurities (Fig. 15).

NOZZLE

The high pressure nozzle fitted on the lance must

be changed from time to time, as this component

is subject to normal wear during use. Wear may

generally be detected by a drop in the working

pressure of the pressure washer. To replace it,

consult your supplier and/or dealer for instruc

-

tions.

DESCALING

Descaling must be carried out, by official service

center only, from time to time because the scale

present in the water partially deposits inside the

hydraulic circuit and the coil which with time be

-

comes clogged.

CLEANING

Use a small soft brush to clean the outside of the

Frequency

PWH 140 PLUS

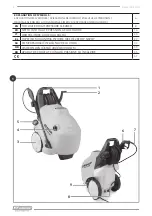

Summary of Contents for PWH 140 PLUS

Page 4: ...4 8 10 9 11 PWH 140 PLUS...

Page 5: ...5 www ffgroup tools com 5 12 13 14 15 PWH 140 PLUS...

Page 27: ...27 www ffgroup tools com CO 0 04 nr 2 Shell Bacharach f PWH 140 PLUS...

Page 28: ...28 f f f IEC 60364 1 3kW IEC 60364 1 3mm 3 kW 30mA 30ms PWH 140 PLUS...

Page 32: ...32 50 100 200 300 500 1 2 3 4 5 14 15 1 2 PWH 140 PLUS...