7

Revision Number-012 01-11-2018 - Present

EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

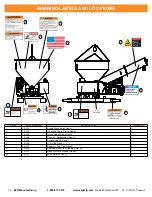

1. Set Grout Hog® securely on ground. Turn off forklift and remove ignition key. Turn off Honda engine

and remove key. Remove skid pins or chain before backing away.

2. Pull spring loaded locking pin on side of hopper and rotate over the release bracket.

3. Firmly grasp the Secondary Pivot Latch Handle, pull to unlock, and lift to dump hopper.

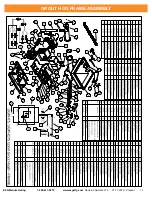

4. Remove end cap with provided speed wrench. Firmly grasp auger handle and pull auger out of tube.

5. Unlatch auger tube section and rotate upward for better access to clean tube. Wash out and brush

down tube, hopper, auger, and end cap.

6. Flush hose until clean.

7. Slide auger back into place over the power shaft connector. Replace end cap on tube.

8. Pull locking pin and rotate hopper to the upright position.

1. Make sure Grout Hog® is clean after each use (see “Cleanup”).

2. Grease fittings before each use. Use EPI GC-LB Rated or equivalent grease.

CLEANUP

CAUTION

Before performing any described maintenance items, make sure engine is off and

hydraulic supply hoses are disconnected. Death or serious injury can result.

WARNING

Verify spring loaded Pivot Latch has hopper securely locked before cleaning.

NOTICE

Be sure to clean all debris from inside the auger drive end.

DANGER

Never run machine with end cap removed.. Death or serious injury will result.

MAINTENANCE

NOTICE

Following each use, it is a good idea to apply a thin layer of lubricant inside the hopper

to make cleaning easier.

CAUTION

Do not use so much lubricant that it might stain blockwork at beginning of next use.

If equipped with crane bail inspect bail, hopper, and base for cracked welds, loose

bolts, and wear before each use. Repair or replace if needed.