www.eyc-tech.com

11

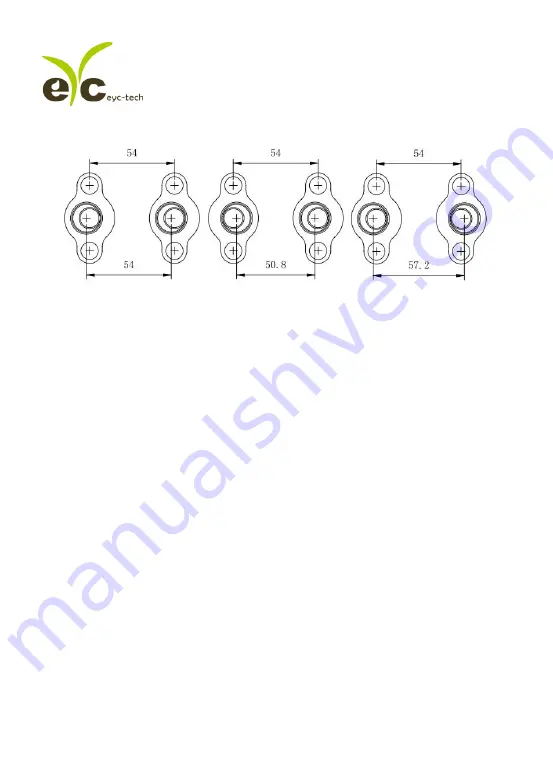

as shown in the figure 2-5

:

Figure 2-5 Connection hole distance of differential pressure transmitter

2.1.4 Installation Precautions

1. Prevent the transmitter from coming in contact with the measured

medium with corrosivity or high temperature (≥ 90 °C).

2. Prevent the dross from depositing in the pressure tube.

3. Get the pressure tube shortened as possible as it can.

4. Keep balance between the liquid heads in the pressure tubes on both

sides of the differential pressure transmitter.

5. Install the pressure tube in a place with small temperature gradient and

temperature fluctuation.

6. Prevent from the crystallization or low-temperature freeze in the

pressure tube.

2.2 Relevant Issues of measurement methods

Liquid measurement:

When measuring the flow rate of the liquid, the pressure tap should be

opened on the side of the process piping to avoid sedimentation of the dross.

At the same time, the transmitter should be installed beside or below the

pressure tap to allow air bubbles to be discharged into the process piping.