Maintenance

Note:

If machine does not pass any of these tests,

do not operate. Contact your authorized

EXMARK

SERVICE DEALER.

Important:

It is essential that operator safety

mechanisms be connected and in proper

operating condition prior to use for mowing.

Check for Loose Hardware

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Visually inspect machine for any loose hardware

or any other possible problem. Tighten hardware

or correct the problem before operating.

Service Air Cleaner

Service Interval: Every 50 hours—Service

the air cleaner. (May

need more often under

severe conditions. See

the Engine manual for

additional information.)

Every 600 hours— Replace

the air cleaner elements.

(May need more often

under severe conditions.

See the Engine manual for

additional information.)

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Loosen retaining clips and remove air cleaner

compartment cover.

3. Remove paper element. Check the condition

of the paper element. Replace if dirty, bent or

damaged.

4. Check the condition of the inner element. Replace

whenever it appears dirty, typically every other

time the paper element is replaced. Clean the base

around the inner element before removing, so

dirt does not get into the engine.

5.

Do Not

wash or use pressurized air to clean

paper element or inner element.

6. Reinstall elements. Position the cover so that the

rubber dust ejector is pointing downward and

secure with retaining clips.

Change Engine Oil

Service Interval: After the first 5 hours

Every 100 hours (May

need more often under

severe conditions.)

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Drain oil while engine is warm from operation.

3. The oil drain hose is located on right hand side

of engine. Place pan under machine to catch oil.

Remove plug from end of drain hose. Allow oil

to drain and replace oil drain plug. Torque plug

to 20-24 ft-lb.

4. Replace the oil filter every other oil change. Clean

around oil filter and unscrew filter to remove.

Before reinstalling new filter, apply a thin coating

of oil on the surface of the rubber seal. Turn

filter clockwise until rubber seal contacts the filter

adapter then tighten filter an additional 1/2 to

3/4 turn.

5. Clean around oil fill cap and remove cap. Fill to

specified capacity and replace cap.

6. Use oil recommended in engine owner’s manual.

Do Not

overfill. Start the engine and check for

leaks. Stop engine and recheck oil level.

Check Hydraulic Oil Level

Service Interval: Every 40 hours

1. Stop engine and wait for all moving parts to stop.

Engage parking brake.

2. Clean area around hydraulic reservoir cap and

remove cap. Oil level should be to the top of the

baffle inside the tank. If not, add oil. Use only

Exmark Premium Hydro oil. Replace hydraulic

reservoir cap and tighten until snug. Do Not

overtighten.

Note:

The baffle is labeled “HOT” and

“COLD”. The oil level varies with the

temperature of the oil. The “HOT” level shows

the level of oil when it is at 225°F (107°C). The

“COLD” level shows the level of the oil when

it is at 75°F (24°C). Fill to the appropriate level

depending upon the temperature of the oil. For

example: If the oil is about 150°F (65°C), fill to

halfway between the “HOT” and “COLD” levels.

24

Summary of Contents for TURF TRACER TT23KAEP

Page 1: ...TURF TRACER TT23KAEP MODEL ONLY For Serial Nos 790 000 Higher Part No 4500 382 Rev A ...

Page 11: ...Safety 103 2432 103 4935 116 0404 11 ...

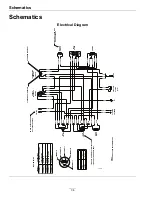

Page 37: ...Schematics Hydraulic Diagram 37 ...

Page 39: ...Notes 39 ...

Page 40: ...Notes 40 ...

Page 41: ...Service Record Date Description of Work Done Service Done By 41 ...

Page 42: ...42 ...

Page 43: ...43 ...