Maintenance

g011735

Figure 30

1.

Feeler gauge

•

If the gap is less than 0.010 inch, then

reinstall the shim and reference the

Troubleshooting

section.

•

If the gap is sufficient, proceed to the

safety check in step F.

F.

Perform the following safety check:

a.

Start the engine.

b.

Make sure the blades Do Not engage with

the PTO switch “off ” and the clutch

disengaged.

If the clutch does not disengage,

reinstall the shim and reference the

Troubleshooting

section.

c.

Engage and disengage the PTO switch

ten consecutive times to ensure the clutch

is functioning properly. If the clutch

does not engage properly, reference the

Troubleshooting

section.

Motion Control Adjustment

Located in the front inside the tower. Rotating the

pump linkage with a 9/16 inch wrench allows fine

tuning adjustments so that the machine does not

move in neutral. Any adjustments should be made

for neutral positioning only.

1.

Prior to starting the engine, pull the deck lift

handle rearward and push the button down, on

the top of the lever, to unlatch from transport.

Lower deck to the ground.

2.

Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

3.

Start engine. Brake must be engaged and motion

control levers out to start engine. Run engine at

full throttle and release brake.

4.

Run the unit at least 5 minutes with the drive

levers at full forward speed to bring hydraulic oil

up to operating temperature.

Note:

The motion control lever needs to be in

neutral while making any necessary adjustments.

5.

Bring the motion control levers into the neutral

position. Access the links from the front of the

tower (Figure 31). Adjust pump control rod

lengths by loosening the bottom nuts on each and

rotating the turn buckle until the wheels slightly

creep in reverse (Figure 31). Pumps have a return

to neutral arms and will return to neutral when

the control levers are released. If the levers do not

fold out, adjust the links until the lever folds out

in the middle of the neutral lock notch. Move the

levers to the full forward and reverse. If the levers

fold out, tighten the jam nuts on the links.

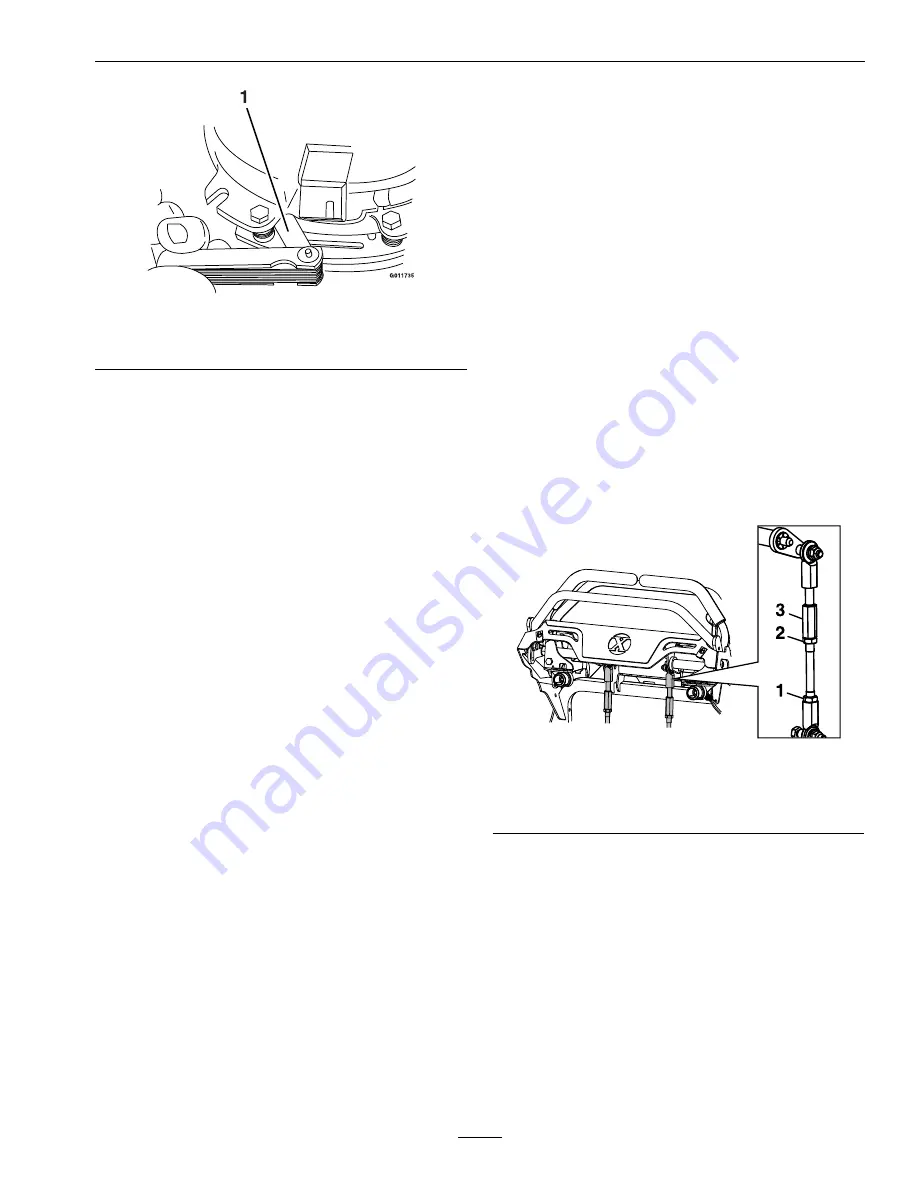

g267312

Figure 31

1.

Lower nut

3.

Links

2.

Upper nut

6.

Shut off unit.

7.

Remove the jack stands.

8.

Raise the deck and re-install the height of cut pin.

9.

Check that the machine does not creep in neutral

with the park brakes disengaged.

Adjust Motion Control

Handle Position

If the motion control levers do not align horizontally,

adjust one or both levers.

43

Summary of Contents for STARIS S Series

Page 1: ...STARIS S SERIES For Serial Nos 408 644 346 Higher Part No 4505 317 Rev A ...

Page 50: ...Schematics Schematics Electrical Schematic Kawasaki g303795 50 ...

Page 51: ...Schematics Electrical Schematic Kohler EFI g303794 51 ...

Page 52: ...Schematics Hydraulic Diagram g304191 52 ...

Page 54: ...Service Record Date Description of Work Done Service Done By 54 ...

Page 55: ...55 ...