Maintenance

Figure 38

1.

Double nuts

8. Shut off unit. Remove jumper wire from wire

harness and plug connector into seat switch.

9. Remove the jack stands.

10. Raise the deck and re-install the height of cut pin.

11. Check that the machine does not creep in neutral

with the park brakes disengaged.

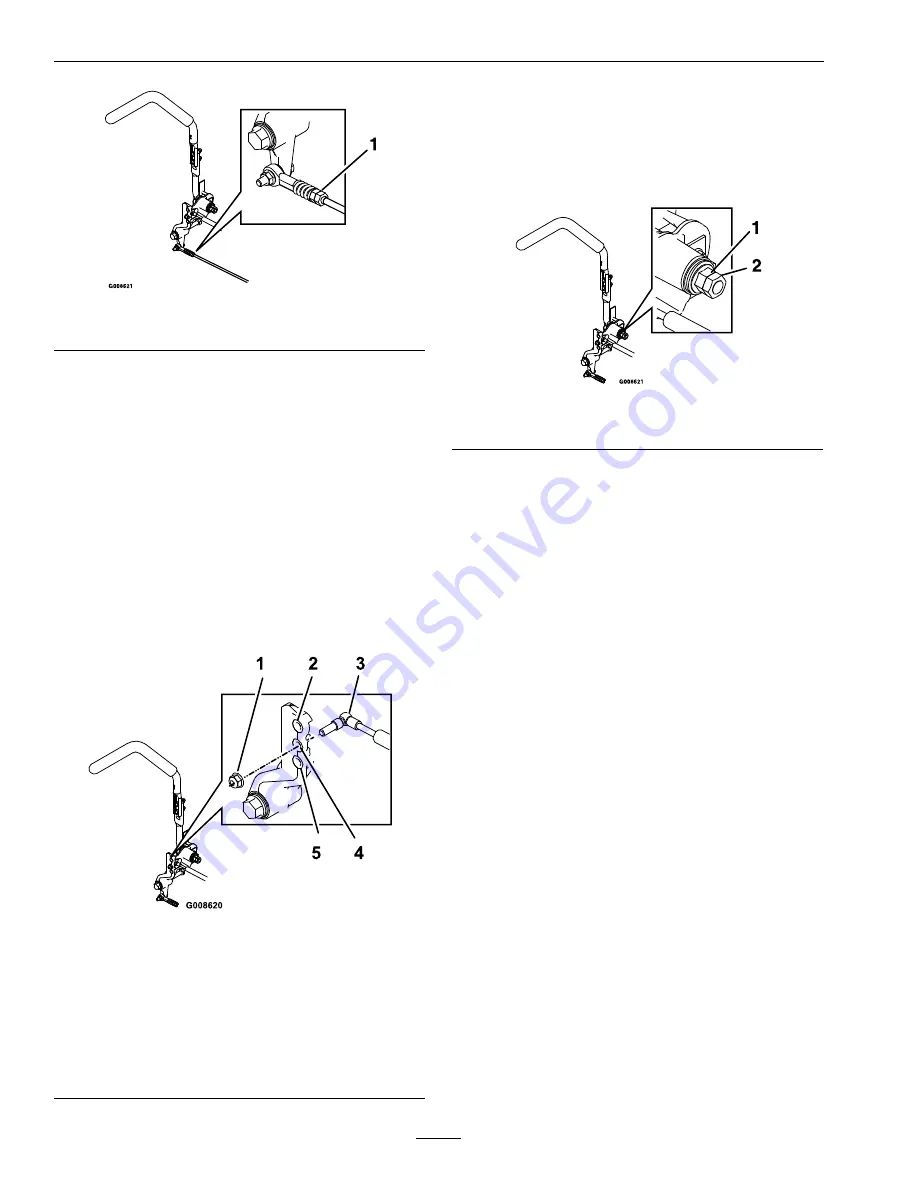

Motion Control Damper

Adjustment

The top damper mounting bolt can be adjusted to

obtain a more desired motion control lever resistance.

See Figure 39 for mounting options.

Figure 39

RH Motion Control Shown

1.

Torque nyloc nut to 200 in-lb (16.7 ft-lb). Bolt must

protrude past end of nyloc nut after torque. A T-40 Torx

bit will be necessary to hold the stud from turning.

2.

Most resistance (firmest feel)

3.

Damper

4.

Medium resistance (medium feel)

5.

Least resistance (softest feel)

Motion Control Neutral Lock

Pivot Adjustment

The flanged nut can be adjusted to obtain a more

desired motion control lever resistance (Figure 40).

Figure 40

1.

Flanged nut

2.

Jam nut

1. Loosen the jam nut.

2. Tighten or loosen the flanged nut to the desired

feel.

For more resistance, tighten the flanged nut.

For less resistance, loosen the flanged nut

3. Tighten jam nut.

Motion Control Handle

Adjustment

Adjusting the height:

The motion control levers can be adjusted higher or

lower for maximum operator comfort.

1. Remove the two bolts holding the control lever to

the control arm shaft (Figure 41).

48

Summary of Contents for Laser Z LZS29PKA604

Page 1: ...LAZER Z PROPANE For Serial Nos 920 000 Higher Part No 4500 720 Rev A ...

Page 16: ...Safety 109 9906 16 ...

Page 57: ...Schematics Hydraulic Diagram 57 ...

Page 59: ...Notes 59 ...

Page 60: ...Notes 60 ...

Page 61: ...Service Record Date Description of Work Done Service Done By 61 ...

Page 62: ...62 ...