PAGE 3

98256C (Rev. A - 4/06)

INSTALLATION

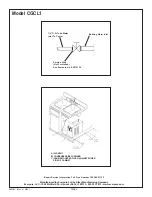

1. This unit is intended to be installed underneath a conventional kitchen sink, in a cabinet not less than 36" (914mm) wide (inside dimension).

Two air openings with a minimum of 40" square (1016mm/square) each, minimum of 75% open area, must be provided in the cabinet. One

opening must be in the overhang of the toe space. The other opening near the top of the cabinet. The remote unit must be installed with a

minimum of 3" clearance between the unit and the rear wall of the cabinet. It can be installed flush against either side wall of the cabinet. The

side louvers which are not against the cabinet must not be blocked by objects located within 4" (102mm) of the louvers. In addition, a minimum of

1 to 2" (25 to 51mm) clearance must be provided between the toe space air opening and front of the unit.

2. Water inlet and outlet are 1/4" (6 mm) O.D. tubes.

3. Connecting lines to be of copper, thoroughly flushed to remove all foreign matter before being connected to cooler.

4. Connect cooler to supply line with a shut-off valve and install a 1/4" O.D. (6 mm) tube. Make sure the cold water connecting to the faucet is

filtered. Use an Everpure Commercial Grade Filter System to provide filtered water. Refer to the Everpure Filter system Install and Operation

Manual for installation procedures.

CAUTION:

Under certain conditions i.e., fluctuations in line pressure, water temperature, intermittent use, it is recommended to use a mini

expansion tank to allow water expansion. See Everpure part number EV310413, not included in box.

5. Electrical: Make sure power supply is identical in voltage, cycle, and phase to that specified on cooler serial plate. Never wire compressor

directly to the power supply.

START-UP

1. Open supply line valve.

2. Purge air from all water lines by using water through faucet. A steady stream assures all air is removed.

3. Rotate fan to insure proper clearance and free fan action.

4. Connect to electrical power.

TROUBLE SHOOTING & MAINTENANCE

Temperature Control:

Factory set at 50°F under normal conditions. For colder water, adjust screw on item no. 10 in clockwise direction.

Ventilation:

Cabinet louvers and condenser fins should be periodically cleaned with brush, air hose or vacuum cleaner. Excess dirt or poor ventilation can

cause no cold water and compressor cycling on the compressor overload protector.

Lubrication:

Motors are lifetime lubricated.

Model CGCL1