- 20 -

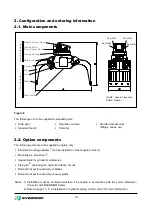

5.5. Adjustment of the rotation device

Pressure Port(RA)

(Counter-clockwise Rotation)

Pressure Port(RB)

(Clockwise Rotation)

Pressure Relief Valve

for Motor

Built-in Relief Valve

(Look from direction A,B)

(A VIEW)

B

(B VIEW)

Stop Valve of

Main Line

Stop Valve of

Rotation Line

A

Figure 15

A built-in relief valve, in which a relief valve to protect rotation motor is built in EVERDIGM hydraulic grab

EPG-series. Do not reset this relief valve because it is set in the factory when delivery. If reset is required,

follow the instructions below.

A built-in relief valve will be seen as Figure 15.

Setting of the relief valve :

Port for pressure check is positioned in both ports

„RA‟ and „RB‟. Place a pressure gauge into either port,

and set the minimum pressure unscrewing the pressure relief valve to the end. The pressure gauge must

be for 400 bar or more.

Place the grab to the ground or the other strong structure so that the grab can not rotate.

Increase pressure by screwing the screw adjuster until the pointer of the pressure gauge reaches the

recommended pressure with the rotation actuator of the carrier switched on. Recommended pressure is

less than 100 bar.

Pay attention to the max pressure since motor life will be reduced if it is used over maximum pressure.

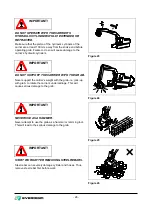

DANGER!

Pay attention to the safety in case a worker is vicinity of working area. Never operate the grab

with workers in close proximity to the grab.

IMPORTANT!

Do not reset the relief valve if possible. The rotation motor life will reduce if the pressure is set

exceeding the allowed pressure.

Summary of Contents for EPG05

Page 36: ...36 Notes...

Page 37: ...37 Notes...