7

Design Considerations (Continued)

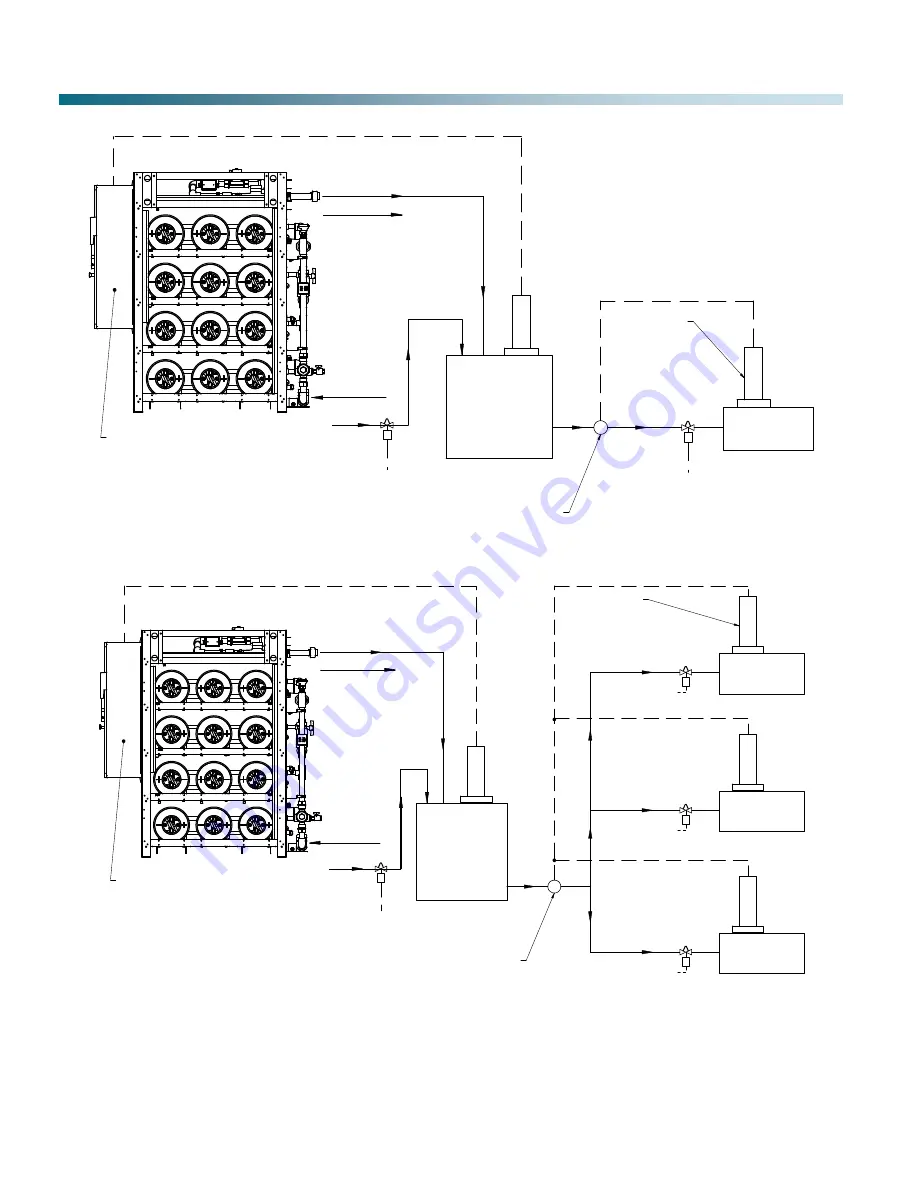

Figure 7: EWS Field Piping/Wiring for Multiple Evaporative Units with Makeup Tank

BOOSTER PUMP REQUIRED

(BY OTHERS)

S

EWS

MAKE UP TANK

MAKE UP

BYPASS

CLEAN OUTLET, PIPE TO PROCESS

FLUSH OUTLET, PIPE TO DRAIN

(NOT IN VIEW)

EWS CONTROL

PANEL

P

E

W

L

C

POWER AND CONTROL WIRING

EWLC REQUIRED

EVAPORATIVE UNIT

S

E

W

L

C

POWER AND CONTROL WIRING

WIRE TO EWLC

ON UNIT

EVAPORATIVE UNIT

BOOSTER PUMP REQUIRED

(BY OTHERS)

EWLC REQUIRED

(TYPICAL)

S

EWS

MAKE UP TANK

MAKE UP

BYPASS

CLEAN OUTLET, PIPE TO PROCESS

FLUSH OUTLET, PIPE TO DRAIN

(NOT IN VIEW)

EWS CONTROL

PANEL

WIRE TO EWLC

ON TANK

P

S

E

W

L

C

POWER AND CONTROL WIRING

E

W

L

C

S

E

W

L

C

S

E

W

L

C

WIRE TO UNIT EWLC

POWER AND CONTROL WIRING

POWER AND CONTROL WIRING

POWER AND CONTROL WIRING

EVAPORATIVE UNIT

EVAPORATIVE UNIT

WIRE TO UNIT EWLC

WIRE TO UNIT EWLC

Figure 6: EWS Field Piping/Wiring for Single Evaporative Unit with a Makeup Tank

WIRE TO EWLC

ON TANK