8

INSTALLATION

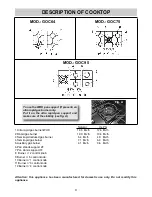

FIG. 4

COMPLY WITH THE DIMENSIONS

(in mm)

A

B

C

D

E

4F (60)

553

473

63.5

63.5

173.5 min.

5F (70)

645

475

63.5

63.5

173.5 min.

5F (90)

833

475

62.5

62.5

73.5 min.

TECHNICAL INFORMATION

FOR THE INSTALLER

This appliance shall be installed only by authorised

personnel and in accordance with the

manufacturer’s installation instructions, local gas

fitting regulations, municipal codes, electrical wiring

regulations, NZS5261:2003, AS 5601 - Gas

Installation and any other statutory regulations.

Ventilation must be in accordance with AS 5601,

NZS5261:2003 - Gas installation. In general, the

appliance should have adequate ventilation for

complete combustion of gas, proper flueing and

to maintain temperature of immediate

surroundings safe limits.

The wall and bench surfaces must be capable of

sustaining temperatures of 75 °C. All laminates,

fixing adhesive and surfacing materials should

be certified suitable for this temperature.

3) INSTALLING THE COOKTOP

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, nails, etc.) within

children’s reach since they could become

potential sources of danger.

The measurements of the opening made in the top of

the modular cabinet and into which the cooktop will be

installed are indicated in fig. 4. The maximum overall

dimensions are shown either in Figures 4/A - 4/B - 4/C.

Always comply with the measurements given for

the hole into which the appliance will be recessed

(see fig. 4).

The appliance belongs to class 3 and is

therefore subject to all the provisions

established by the provisions governing such

appliances.

Any adjoining wall surface situated within 200 mm

from the edge of any hob burner must be a suitable

non - combustible material for a height of 150 mm

for the entire length of the hob. Any combustible

construction above the top of the burner and no

construction shall be within 450 mm above the top

of the burner. A minimum depth of 70 mm from the

top of the work surface must be provided for this

appliance.

CAUTION:

the installer shall test the appliance

before leaving. Test the safety

operation of the ignition system on all

burners individually and combined.

IMPORTANT: a perfect installation,

adjustment or transformation of the cook top

to use other gases requires a QUALIFIED

INSTALLER: a failure to follow this rule will

void the warranty.

Fig.4/A

Mod.:GOC64

Fig.4/B

Mod.:GOC75

Fig.4/C

Mod.:GOC95