Instruction Manual ZHK

102/129

V07-19.0

-

The fan bearings are lubricated for life. Except the pillow block bearings of larger fans, with de-

manding operating conditions, should be lubricated annually in accordance with

be-

low and this should be done with lithium soap grease (see

) for recommended grease

types. After three lubrications the bearings must be removed, cleaned and greased again.

Ambient conditions

Temperature range °C

Lubrication interval

Clean

T < 50

6 - 12 month

50 < T < 70

2 - 4 month

70 < T < 100

2 - 6 weeks

100 <

1 week

Dusty

T < 70

1 - 4 weeks

70 < T < 100

1 - 2 weeks

100 < T

1 - 7 days

Extreme humidity

1 week

Table 13:

Lubrication intervals for fan bearings

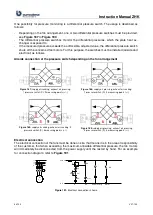

Figure 199:

Fan bearing with grease nipple

(example Comefri NTHZ)

Supplier

Type

Basis

Temp. range

FINA

Marson HTL 3

Lithium

30 °C / +120 °C

SHELL

Alvania Fett 3

Lithium

-20 °C / + 130 °C

ESSO

Beacon 3

Lithium

-20 °C / + 130 °C

MOBIL

Mobilux EP3

Lithium

-30 °C / + 130 °C

Table 14:

Recommended grease types

Plug fan

-

The fan is directly flanged to the motor and due to the absence of the belt drive it is a service

friendly component.

-

To reach the operating point, a frequency converter is required.

-

Danger: Deposits on the wheel can cause damage (risk of fatigue fracture) and the impeller can

break!

-

Visual inspection: Check the wheel for any particular weld cracking.

Summary of Contents for ZHK Series

Page 1: ...ZHK INSTRUCTION MANUAL ...