Page 7

3101 Mt Carmel Ave. Glenside, PA │ 833-ENV-GURU (833- 368-4878)

IV. Operation

•

Air is drawn (from the chamber) into the input hose barb (mounted to the lid), passed through

the pump and comes out through the fitting on the opposite side of the lid.

•

The fitting is attached to the column with a short length of tubing. The air passes though the

tubing, into the “IN” fitting on the column lid.

•

The air is forced to the bottom of the column. It then passes through the desiccant as it returns

to the “OUT” fitting on the column lid.

•

The dried air is then sent back to the chamber.

•

Both input and output have filter pads to cut down on desiccant dust.

V. Description and Specifications

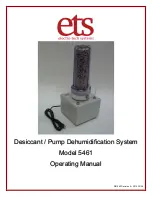

The Model 5461 Desiccant Dehumidification System is a closed loop system, designed to reduce the relative

humidity within a sealed chamber to less than 10%. When used with an Automatic Humidity Controller, such as the

ETS Model 5100 or Model 5200 Microprocessor Humidity Controllers, the chamber may be maintained to within

± 0.1% RH of the set-point.

A clear plastic column filled with 1 Liter of renewable Molecular Sieve

(“MS”) desiccant is mounted to the top of the

enclosure. The desiccant removes moisture from the air. The dried air is forced back into the chamber by small,

quiet linear air pump mounted inside the enclosure.

Twenty percent (20%) of the MS granules are indicating granules, visible as the blue granules in a fresh system.

These turn to gray when the MS material has adsorbed its full capacity of water. At this point, the MS needs to be

renewed or replaced. The column is easily removable for replacing the desiccant. See Section VII for instructions.

The desiccant can be renewed approximately ten (10) times before having to be replaced.

SPECIFICATIONS

•

The average flow rate from the unit is 0.54 cfm (15 lpm).

•

The air is dried to a dewpoint of -100

⁰F.

•

Capacity for water vapor up to 100 grams.

•

Power

– 115 VAC/60 Hz, 0.35 Amps, or 230 VAC/50 Hz, 0.18 Amps

•

Desiccant Column is safe for working pressures up to 100 psig.

•

Contents: 1 Liter of Molecular Sieve Desiccant.

•

Connections are for ¼” OD tubing.

•

Plastic cap is fitted with “O-Ring” gasket.

•

Desiccant coil spring is made of cadmium plated steel.