3

www.etna.com.tr

01. Introduction

Read this manual carefully before installing and using

the product. Improper use of the product can cause

personal injury and damage to property and may void

the warranty. When ordering spare parts use page 15.

02. Use of Booster Set

Water is usually delivered by public supply systems

and the pressure is generally sufficient for the proper

operation of the user's water and sanitary equipment.

When this pressure is not sufficient, booster sets are

installed to increase water pressure and ensure an

acceptable minimum value at the furthest points.

Therefore, the water supply to a building, group of

buildings or to a system, in general, can be considered

satisfactory when all the user points can deliver the

required quantity of water.

03. Schematic Booster Set Connection

Method

Water is supplied by installing a water storage tank

between the users off take and booster set. (Fig.1)

04. Handling

When the booster unit is delivered, check that it has not

been damaged during shipping. Promptly inform our

nearest dealer, if necessary. Do not use the eyebolts,

expansion tanks, inlet and discharge manifolds etc., as

they are not designed to bear the weight of the booster

set. The product must be handled with care using

suitable hoisting equipment; accidents can damage

the product without being necessarily visible on the

outside; hoisting non-packed products by securely

putting them into a sling from the main chassis. Please,

put the unit on to the floor, gently.

05. Applications

The booster sets are suitable for water handling

systems in the civil, industrial and agricultural sectors,

for pressure boosting water supply for small houses,

buildings, factories, industrial plants, holiday villages

and water treatment plants.

They are not suitable for;

• Liquids containing abrasives

• Liquid with solid and fibrous substances - Flammable

and explosive liquids

06. Installation

For booster unit lifting and moving sling it safely. The

unit should not be exposed to the weather or freezing

temperatures. Make sure that there are no obstacles,

preventing normal flow of the cooling air moved by

the motor fan. The booster set must be put on to a

horizontal concrete base or equivalent structure by the

4 pieces of rubber supports, which are provided with

the unit. The bigger industrial models must be firmly

secured by means of appropriate bolts to a concrete

base.

07. Suction and Discharge Pipes

Use pipes suitable for the maximum booster set

working pressure. The suction pipe must be perfectly

sealed and of suitable size for the suction conditions

(suction pipe Ø ≥min. inlet manifold Ø of the booster

set or pump). When the liquid level is lower than the

booster set, a foot valve must be fitted at the end of the

suction pipe (see Fig.2) (Fig.3)

Mains

Water Tank

p min

≥

1.5 bar

p max

≤

5 bar

Drainage

Consumption Points

Booster Set

Figure 1

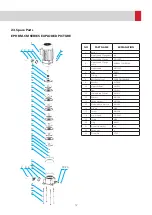

Summary of Contents for EPH B-M46 Series

Page 11: ...11 www etna com tr 22 Electric Panels for Single and Double Pump...

Page 33: ...33 www etna com tr NOTES...

Page 34: ...34 NOTES...

Page 35: ...35 www etna com tr NOTES...