Finalize Hoist and Cable Management Installation

22

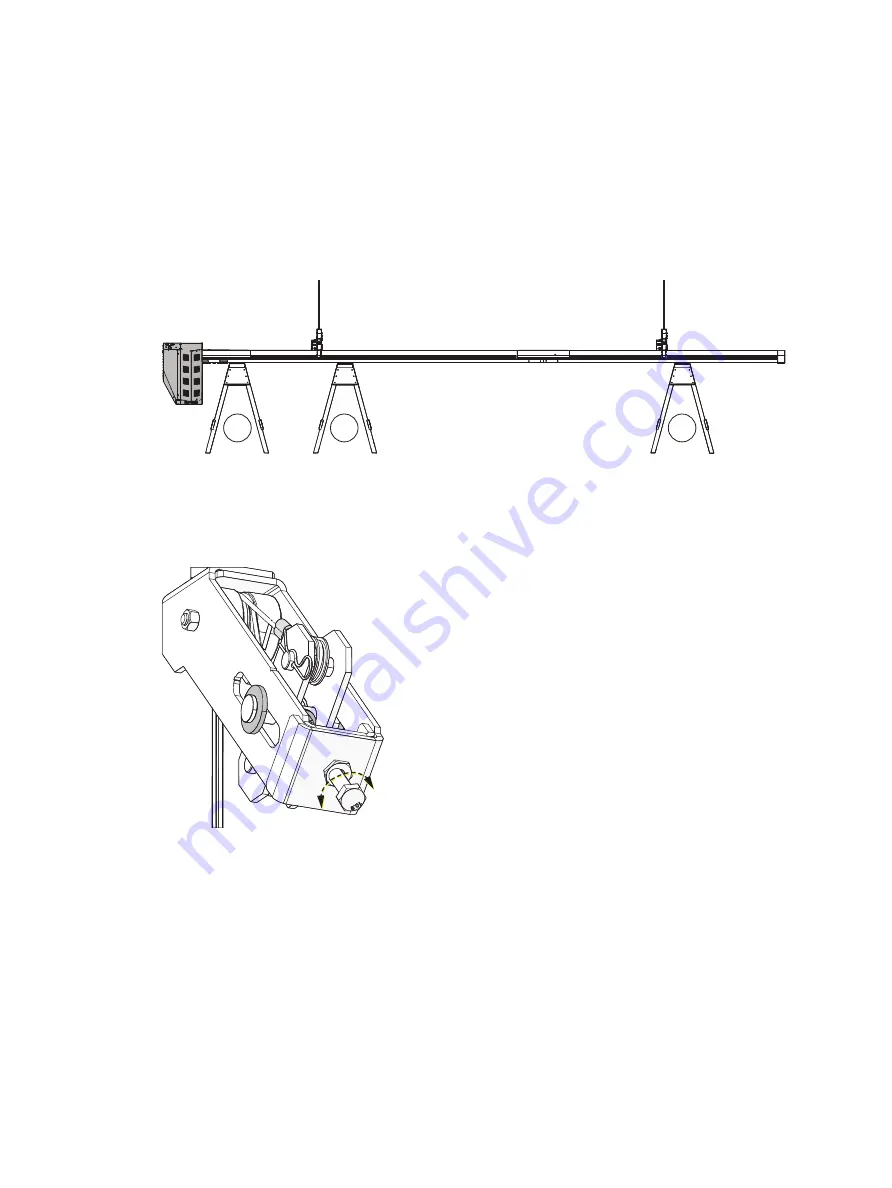

Float the Hoist

Prior to running the hoist, you must ensure that all TwinLine sets are held taut. To accomplish

this, lift the hoist off of the stands or sawhorses on which it is resting. If you have multiple people

available, lift the hoist off together, keeping it as level as possible and lowering it so that all of

the lift lines are tensioned the same.

If you must float the hoist alone, lift each section of the hoist off each stand individually, starting

at the motor end. Once you have lowered each section of the hoist, ensure that the lift line

terminations are tensioned equally. If you run the hoist up with slack lines, you could cause

damage to the hoist.

1

2

3

Level the Hoist and Test Movement

If it is necessary to adjust the trim so your hoist is level, use a 17 mm socket wrench to adjust the

trim of the TwinLines. If you need to remove extra slack from the lift line, turn the adjustment

bolt clockwise. If you need to add slack, turn the bolt counter-clockwise.

Test Hoist Movement

Bump the hoist in the up direction and listen for any unusual noises. STOP immediately if any

unusual noises occur and call ETC technical support.

Install Slack Line Sensor Kit

If you are installing a FlyPipe-XL model hoist, you must install the sensor kit that ships with the

hoist before operation. For more information, refer to the

Prodigy FlyPipe Slack Line Sensor Kit

Installation Guide

that is included in the sensor kit packaging.