9

EST 246

COMMISSIONING

Before commissioning it is necessary to clean the sprayer from

preservation substances using a suitable degreasing agent – flush

the sprayer with solvent for coating substances which will be applied.

Each sprayer is adjusted and tested in the production plant

(quality test).

u

se

the

hose

for

the

supply

of

the

compressed

air

:

»

within 10 metres with the clearance of

8 mm

»

over 10 metres with the nominal clearance of

9.5 mm

o

ptions

for

selecting

the

supply

of

painting

substances

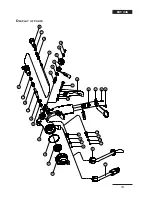

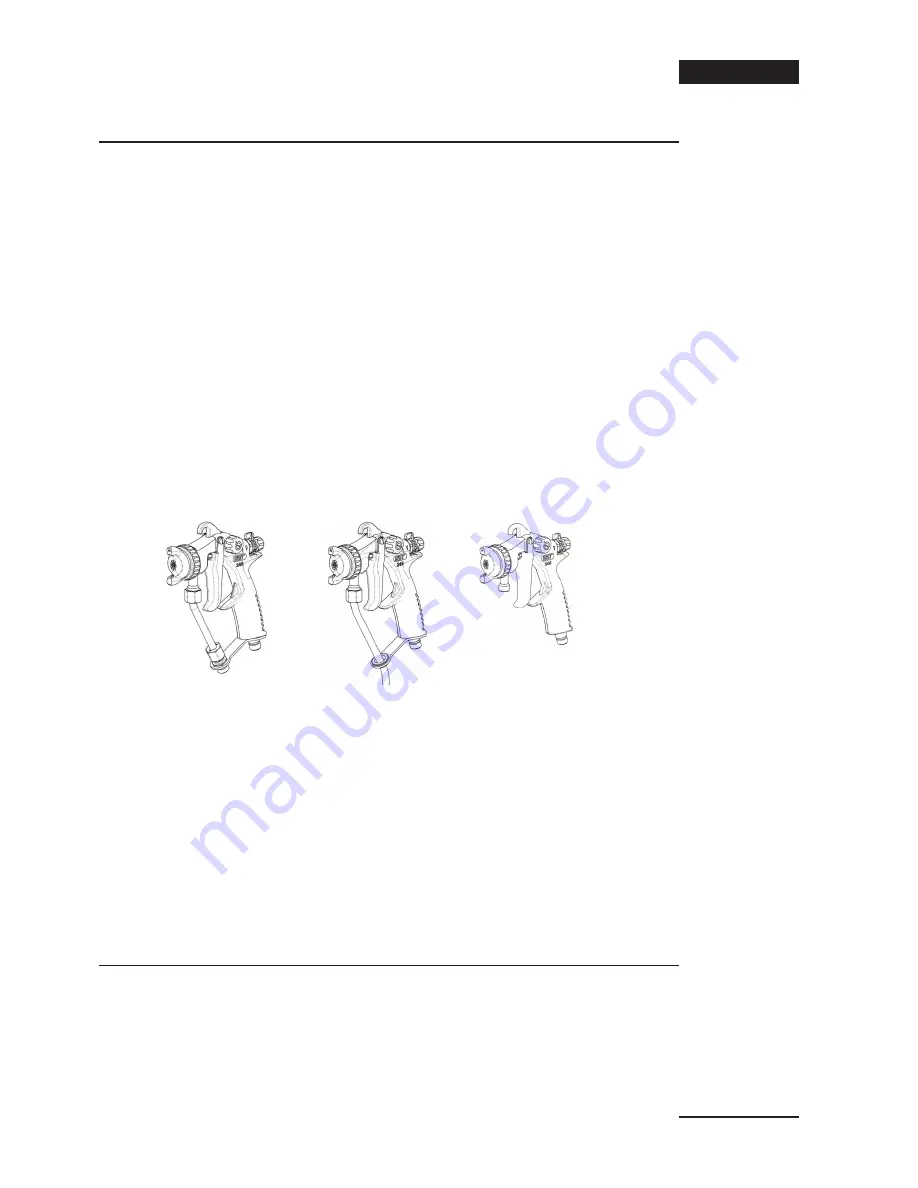

The construction of the EST 246 A sprayer has the option to select

the supply:

»

lower fixed supply – stainless tube with connecting threading

M 14 x 1.5

»

flexible lower supply – calibrated hose, e.g. Pa, Pu 8/6 and 6/4

»

lower supply, standard version - threading M 14 x 1,5

d

irect

connection

of

fast

couplings

for

the

air

on

the

sprayer

The construction of the sprayer enables to connect air fast

couplings to the sprayer. The fast coupling drift from RECTUS, type

26 SFIW 13, can be attached onto the supply threading.

The producer recommends using branded fast couplings with low

pressure loss and long service life.

For the air supply, it is possible to use a fast coupling only

during the application of water-borne coating substances

which do not require electrostatic leakage.

SPRAYER ADJUSTMENT

While complying with the basic requirements for maintenance, the

sprayer does not need any adjustment. Each sprayer is adjusted and

tested in the production plant. During dismantling and assembling

due to replacing the jet set or worn parts, it is necessary to check

the adjustment of the following parts:

Summary of Contents for 246

Page 23: ...23 EST 246 ...