-- 33 --

bm16d12e

3

INTRODUCTION

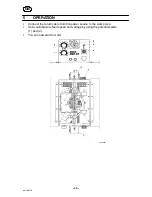

A10-- MEK 25

is an intermediate wire feed unit for MIG/MAG--welding where the

electrode is fed forward according to ESAB:’s A10--system

By connecting an extension cable between the intermediate wire feed unit and the

wire feed unit on the power source the working radius can be increased by up to

25 m.

On

MEK 25

the wire feed speed and the voltage can be controlled using

potentiometers or a remote control unit can be connected.

The drive motor is of a permanent--magnetic design and is integrated with a worm

gear. The motor is fed with 24 V DC voltage.

MEK 25

is equipped with a heavy--duty crash bar and runners to facilitate transport.

The extensive range combined with the performance of the power source provides

you with a flexible total solution.

3.1

TECHNICAL DATA

Control voltage

42V AC

Voltage

0--24V DC

Wire feed speed

1--18m/min

Feed roller hollow wire

1,0--1,2 R / 1,4--1,6 R

Feed roller solid wire

1,0--1,2

Enclosure class

IP 23

Weight

7,5 kg

Continuous A--weighted noise level

58 dB

Enclosure class

The

IP

code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked

IP 23

is designed for indoor and outdoor use.

GB