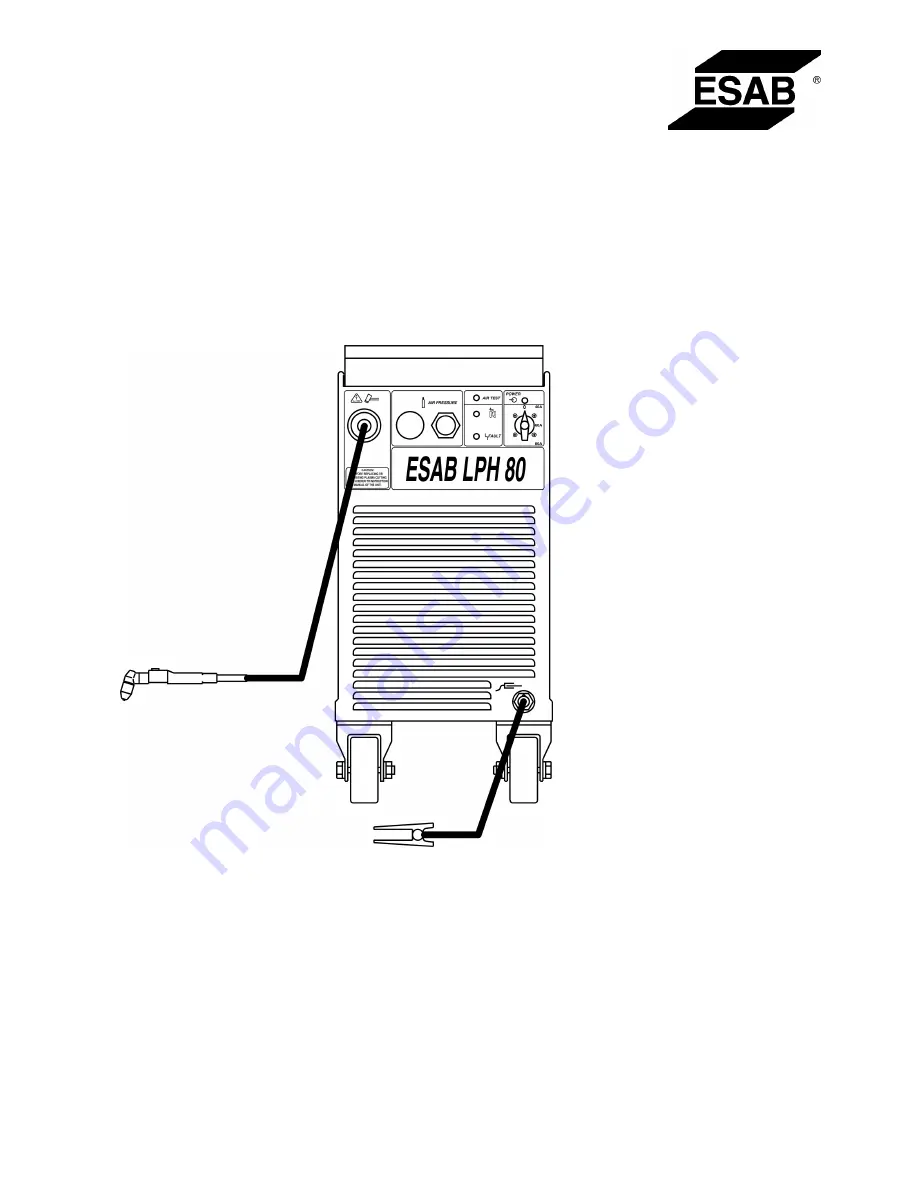

LPH 80

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction Manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Instruzioni per l’uso

Manual de instruções

Οδηγίες

χρήσεως

Instrukcja obs

ł

ugi

0349 30

1

028

0

1

0320

Valid for serial no.

11

2-xxx-xxxx