Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

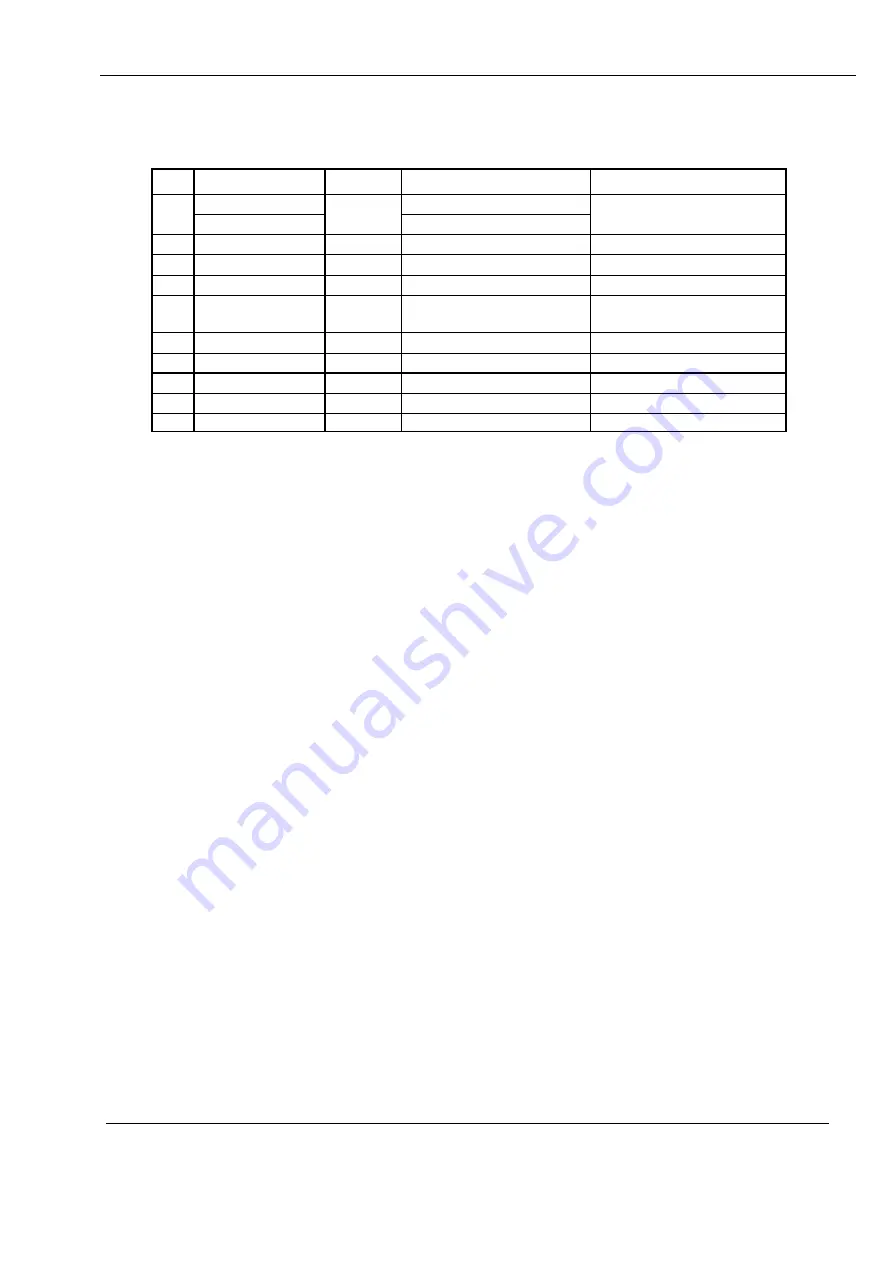

Parts list for ERHARD NON SLAM Nozzle Check Valves DN 350 – 600

with standard materials

Item Description

Qty.

Material

Notes

Body 350 - 400

EN-JS1030

Body 500 - 600

EN-JS1025

2

Internal body

1

2.1050.01

zinc-free bronze

3

Threaded pin

4

A4

stainless steel

4

Bush

8

High-performance polymer

5

Piston ring

1

1.4404/EPDM

vulcanised

EPDM

rubber-

coating

6

Guide rod

4

1.4057.05

stainless steel

7

Pressure spring

4

1.4310.07

stainless steel

8

Threaded bush

4

A4

stainless steel

9

Washer

4

NBR or EPDM

10

Cover

1

2.1050.01

zinc-free bronze

ductile cast iron

1

1

Corrosion protection for DN 80 – 600:

The body is internally vitreous-enamelled and externally EKB coated (synthetic epoxy

coating). All other parts are made of stainless materials.

Recesses are provided at the centering of the internal body in the main body so that the

transitions between the uncoated and coated surface can be filled with sealing agent.

This protects and seals these critical areas against the flow medium.

1.3 Performance and Mode of Operation

The ERHARD NON SLAM Nozzle Check Valve is a flow-controlled non-return valve

with centrally and axially moved obturator. This obturator with the shape of a valve disc

(DN 80 – 300) or a valve ring (for DN 350 and larger) is guided by means of one (four) a

guiding stem(s) in an internal body. The closing movement of the valve is spring-

assisted (one or four springs).

The ERHARD NON SLAM Nozzle Check Valve is resilient-seated, with tight closure

according to DIN EN 12266 / 1074 – leakage rate 1 (0 drop per minute), at a minimum

back pressure of 4.0 mWC (400 mbar) and larger for DN 80 – 300 and a minimum back

pressure of 8.0 mWC (800 mbar) and larger for DN 350 – 600.

The valve starts opening at incipient velocity and is fully open at a velocity of approx. 2

m/s. The opening process can be influenced by a special spring which is designed for

special cases of application.

The standard design is suitable for installation in horizontal pipeline and for vertical

pipeline and for vertical upward flow. When the valve is installed in a vertical pipeline

with downward flow, the ERHARD NON SLAM Nozzle Check Valve has to be equipped

with a special spring. Moreover, a remachined internal body is used which is designed

with additional bores for drainage of the internal body (see fig. 1.1 and 1.2).

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG

x

D-89502 Heidenheim

x

Postfach 1280

Telefon: (07321) 320-0

(07321) 320 491 E-Mail: info

@

erhard.de

Internet: http://www.erhard.de

Page 8 of 18