Troubleshooting

Troubleshooting When There is No Error Display

3.3 Troubleshooting When There is No Error Display

3.3.1 Troubleshooting for Printer

This section describes repair/service of the Printer Mechanism. Listed below are various problems which may occur, observations of such problems, check point and remedies.

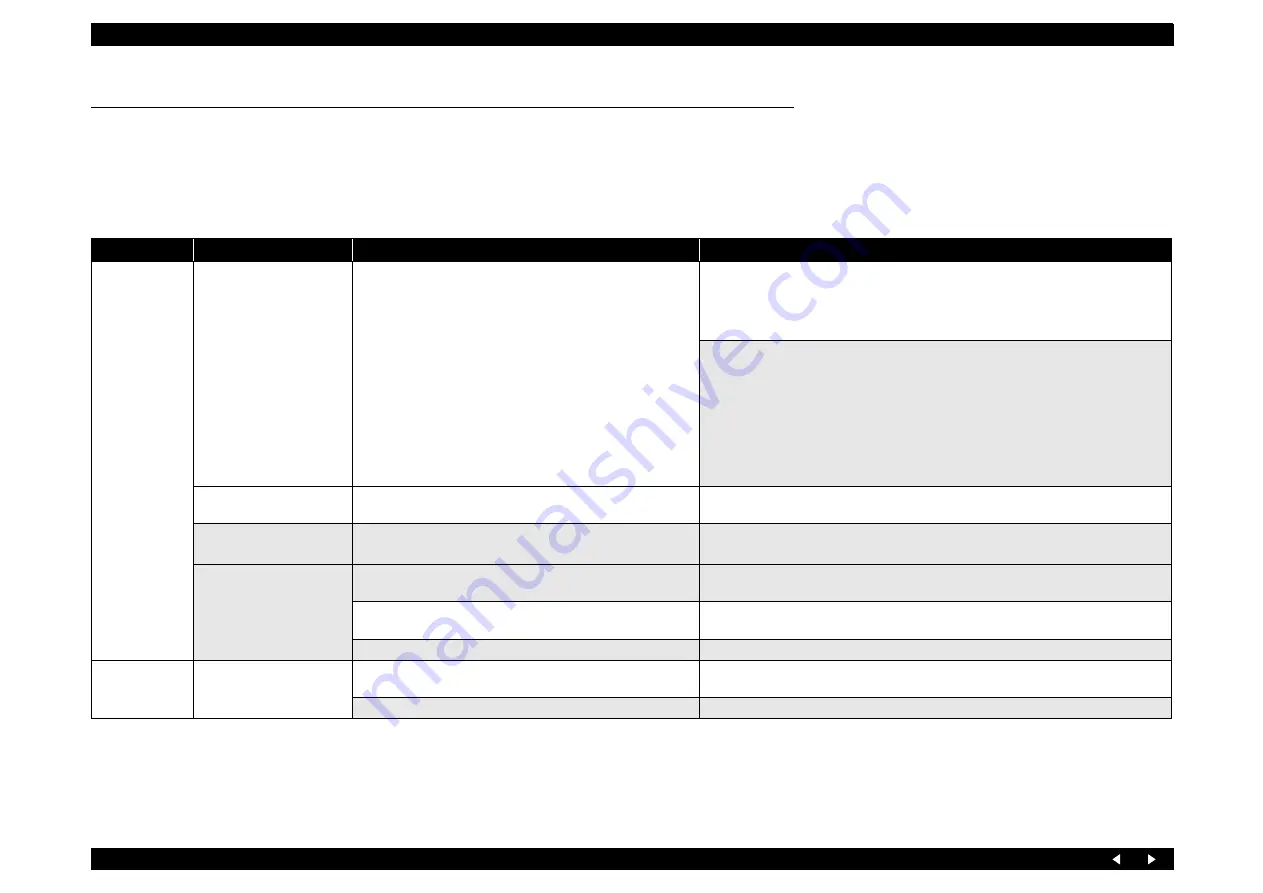

Faulty paper loading

Table 3-1. Diagnostics when feeder is abnormal

Condition

Cause

Check Point

Remedy

Paper is not

loaded.

LD Roller and Retard Roller

dirty or worn

Check to see if no Micro Pearl or oily substance is adhering to

the paper loading roller.

Clean the rollers using a cleaning sheet.

1. Set a cleaning sheet upside down in the ASF Assy.

2. Start paper feed with the panel button.

3. Repeat steps above several times.

To remove oils from rollers, staple a cloth dampened with alcohol to a postcard

and follow the steps below.

1. Set the postcard in the tray with the alcohol dampened cloth side facing the LD

Roller (or Retard Roller).

2. Start paper feed while firmly holding the upper edge of the card.

3. Repeat the paper feed operation several times to clean the surface of the LD Roller

(or Retard Roller).

If these steps do not correct the problem, replace both the LD Roller and Retard Roller.

Pick Up Roller and Idle

Roller dirty or worn

Check to see if no Micro Pearl or oily substance is adhering to

the rollers.

Wipe the rollers with a cloth dampened with alcohol.

Operation of paper loading

mechanism is abnormal

Check to see if there is no abnormality in the paper loading

mechanism.

Adjust the phase of the paper loading mechanism.

Remove the dust and dirt, if any.

PE Sensor/PE Lever

not operating properly

Check to see if the PE Sensor connector has not been

disconnected from the sensor or Main Board.

Connect the PE Sensor connectors to the sensor and Main Board CN10 properly.

Check to see if the Torsion Spring has been set on the PE Lever

properly.

Install the Torsion Spring on the PE Lever properly.

Check for damaged PE Sensor.

Replace the PE Sensor.

Several sheets of

paper are fed at

the same time

Retard Roller operation is

abnormal

Check to see if the tension spring on the Retard Roller is

disengaged.

Install the tension spring properly.

Check to see if the Retard Roller is out of position.

Install the Retard Roller properly.

Summary of Contents for Stylus Photo RX640 series

Page 1: ...EPSON StylusPHOTORX640 650 Scanner Printer Copier SERVICE MANUAL SEMF05003 ...

Page 8: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 15: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 19: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 40: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 71: ...C H A P T E R 5 ADJUSTMENT ...

Page 77: ...C H A P T E R 6 MAINTENANCE ...

Page 82: ...C H A P T E R 7 APPENDIX ...

Page 87: ...Model PM A890 Stylus PHOTO RX640 650 Board C608Main Sheet 1 3 Rev D ...

Page 88: ...Model PM A890 Stylus PHOTO RX640 650 Board C608Main Sheet 2 3 Rev D ...

Page 89: ...Model PM A890 Stylus PHOTO RX640 650 Board C608Main Sheet 3 3 Rev D ...

Page 90: ...Model PM A890 Stylus PHOTO RX640 650 Board C608PNL Sheet 1 1 Rev A ...

Page 91: ...Model PM A890 Stylus PHOTO RX640 650 Board C608PNL B Sheet 1 1 Rev C ...

Page 92: ...Model PM A890 Stylus PHOTO RX640 650 Board C608PSB Sheet 1 1 Rev B ...

Page 93: ...Model Stylus PHOTO RX640 650 Board C608PSE Sheet 1 1 Rev B ...

Page 94: ...Model PM A890 Stylus PHOTO RX640 650 Board C608ISN Sheet 1 1 Rev D ...

Page 96: ...400 100 101 PM A890 EPSON Stylus Photo RX640 650 No 1 REV 01 C608 ACCE 001 ...

Page 98: ...544 202 110 109 108 300 200 PM A890 EPSON Stylus Photo RX640 650 NO 3 REV 01 C608 ELEC 001 ...