Troubleshooting 5

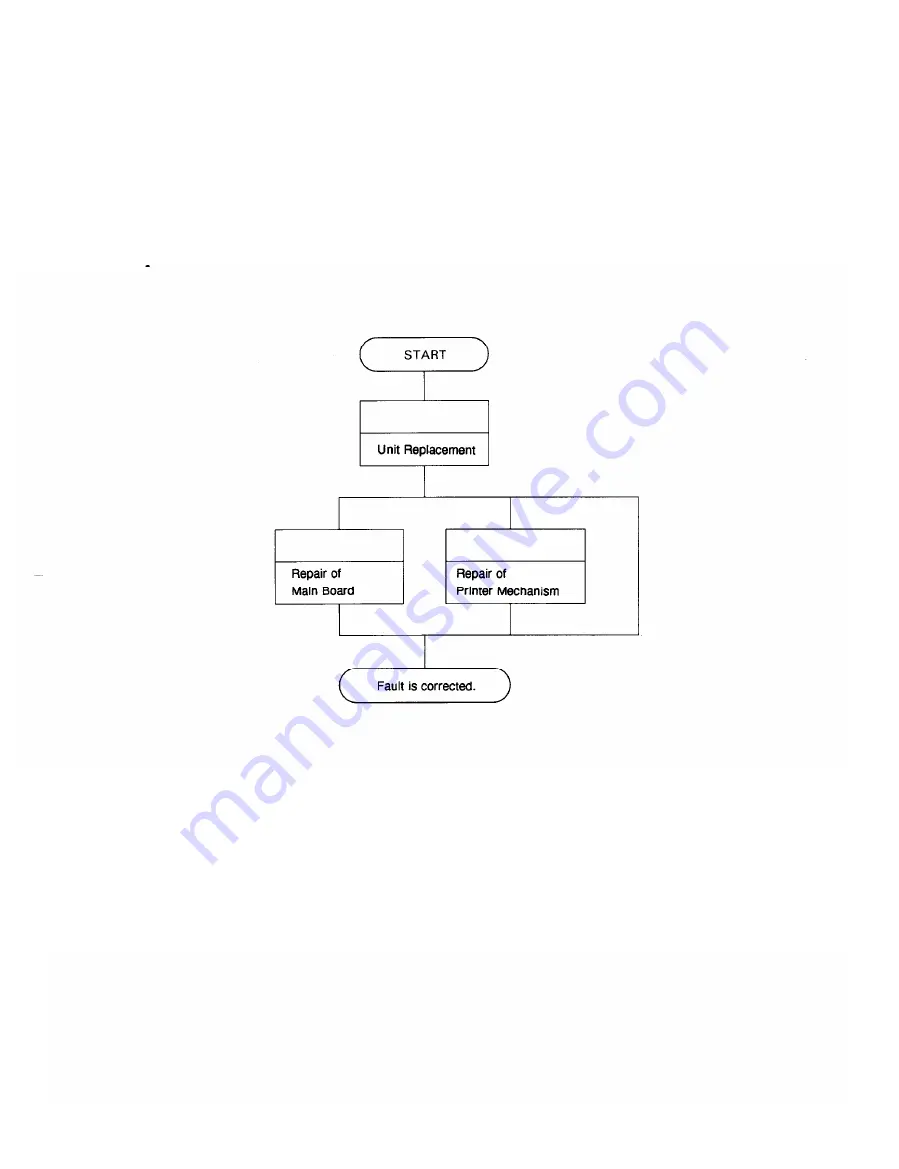

Procedure for Troubleshooting the Printer

Printer problems may produce a variety of symptoms that complicate the task of

troubleshooting. However, you can simplify this process by following the

procedure outlined in the flowchart below.

Figure 5-1. Troubleshooting Procedure

Unit Replacement

For most problems, it is sufficient for you to determine the difficulty to the unit

level. Refer to Table 5-1; determine what the problem is; then follow the checks

provided in the corresponding flowchart.

LQ-2OO/AP3000

5-1

Summary of Contents for ActionPrinter 3000

Page 1: ...EPSON LQ 200 ActionPrinterTM 3000 Service Manual Revision Level I Printed on recycled paper ...

Page 21: ... Normal character General Description Figure 1 5 Character Matrix LG 200 AP3000 1 13 ...

Page 97: ...Principles of Operation Figure 2 51 A D Converter Circuit LQ200 AP3000 2 53 ...

Page 101: ...Principles of Operation Figure 2 53 Ribbon Feed Mechanism LQ 200 AP3000 2 57 ...

Page 153: ...Table 5 1 Symptoms and Reference Pages 5 2 LQ 200 AP3000 ...

Page 155: ...Troubleshooting Abnormal Carriage Operation LQ 2OO AP3000 ...

Page 157: ...Troubleshooting Figure 5 2 Printhead Resistance 5 6 LQ 200 AP3000 ...

Page 158: ...Abnormal Paper Feed but Normal Printing LQ200 AP3000 5 7 ...

Page 159: ...Troubleshooting Abnormal Operation of the Control Panel 5 8 LQ 200 AP3000 ...

Page 162: ...Table 5 2 Repair of the Main Board cont LQ 2OO AP3000 5 11 ...

Page 163: ...Table 5 2 Repair of the Main Board cont 5 12 LQ 200 AP3000 ...

Page 164: ...Table 5 2 Repair of the Main Board cont LQ 200 AP3000 5 13 ...

Page 165: ...Troubleshooting Table 5 2 Repair of the Main Board cont 5 14 LQ 200 P3000 ...

Page 166: ...Table 5 2 Repair of the Main Board cont LQ 200 AP3000 5 15 ...

Page 167: ...Troubleshooting Table 5 2 Repair of the Main Board cont 5 16 LQ 2OO AP3000 ...

Page 169: ...Troubleshooting Table 5 3 Repair of the Printer Mechanism cont 5 18 LQ 2OO AP3000 ...

Page 170: ...Troubleshooting Table 5 3 Repair of the Printer Mechanism cont LQ 2OO AP3000 5 19 ...

Page 175: ...Maintenance Figure 6 2 LQ 200 AP3000 Lubrication Points 6 4 LQ 200 AP3000 ...

Page 178: ...Appendix Table A l Board Connector Summary A 2 LQ 200 AP3000 ...

Page 179: ...Circuit Diagrams Figure A 2 C064 MAIN Board Circuit Diagram A 3 LQ 200 AP3000 ...

Page 180: ...Appendix Figure A 3 PEBFILL_II Board Circuit Diagram LQ 2OO AP3000 A 5 ...

Page 181: ...Appendix A 6 Figure A 4 Control Panel Circuit Diagram LQ 200 AP3000 ...

Page 183: ...Appendix Exploded Diagrams Figure A 6 LQ 200 AP3000 Exploded Diagram LQ 200 AP3000 ...

Page 184: ...Appendix Figure A 7 M 5C1O Printer Mechanism Exploded Diagram LQ 200 AP3000 A 9 ...

Page 185: ...A p p e n d i x Figure AS Tractor Exploded Diagram A 10 LQ 200 AP3000 ...

Page 186: ...Table A 2 Part Number Reference Table Note ESG Epson standard gray A 11 ...

Page 188: ...Appendix Figure A 10 LQ 200 AP3000 Case Outline Drawing with Tractor Unit LQ 200 AP3000 A 13 ...

Page 189: ...Appendix Table A 3 Connector CN3 on the CM4 MAINBoard A 14 LQ 2OO AP3000 ...

Page 191: ...Appendix Table AS Connector CN5 on the C064 MAINBoard A 16 LQ 200 AP3000 ...