EX-5100 C

OMBUSTIBLE

ENMET

9

5.2 Calibration of the EX-5100

Calibration is the process of setting the instrument up to read accurately when exposed to a target gas. The Zero function sets

the clean air reference point and the Span function sets the sensitivity of the instrument.

Initial Calibration:

Wait 24 hours after initially supplying power to the

EX

-

5100

sensor/transmitter (S/T) before initial calibration. The S/T has

been precalibrated at the factory, and initial field calibration should result in only fine tuning to circuit, as well as a way to

check that installation is successful. It is not necessary to open the enclosure to make adjustment; the span and zero

potentiometers are operated with magnets from outside the enclosure. Do Not open the S/T unless the area is de-classified.

Calibration Zero and Span functions are two separate procedures. They operate independently of each other. It is

recommended that the Zero procedure be done prior to the Span procedure.

ENMET

recommends at least quarterly calibration

of the

EX-5100

transmitters.

Calibration equipment is available from

ENMET

to calibrate the

EX

-

5100

sensor/transmitter. A calibration adapter will have a

fitting for the gas cylinder on one side and a cover to go over the sensor housing on the other.

Generally, a cylinder of 20.9% Oxygen is used to provide a fresh air reference or Zero point for the calibration. Another

cylinder is used to provide the Span reference point for calibration. Depending on the instrument calibration, the Span gas may

be the same gas that the instrument is calibrated to display, or it may be another gas, which

ENMET

has found to have a similar

response.

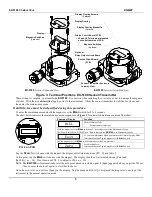

Figure 4: Calibration Adapter EX-5100 Sensor/Transmitter

S

e

le

c

t

M

e

n

u

Select

Menu

Fitting to

calibration cover

Regulator

Gas Cylinder

Calibration Cover

p/n 03620-015