13

IOM, WD Models

Enertech Global

Features

Enertech Global geothermal heat pump controls leverage a

modular approach for controlling heat pump operation. The

control system uses a combination of printed circuit boards,

depending upon the features equipped in a particular unit.

This approach simplifies installation and troubleshooting, and

eliminates features that are not applicable for some units.

Section 7: Controls

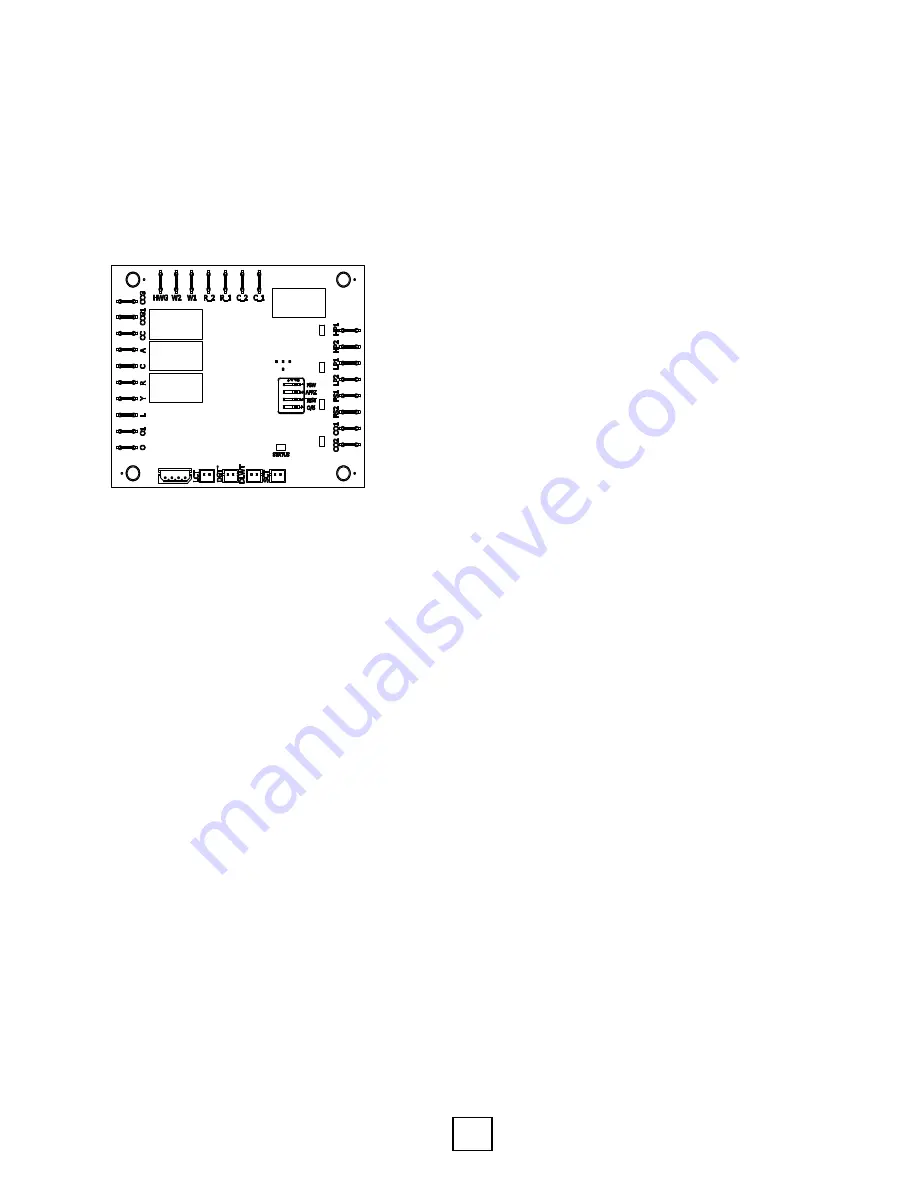

Lockout Board Layout

20D239−01NN

REVISION HISTORY

REV

DESCRIPTION

ECN

DATE

APPROVED

A

INITIAL RELEASE FOR UPDATED CONTROLS

SECTION IN IOM

4−29−16

KW

GREEN

HIGH PRESSURE

ORANGE

LOW PRESSURE

RED

FLOW SWITCH

YELLOW

CONDENSATE

OVERFLOW

GREEN

STATUS

ICM LOCKOUT BOARD

The Lockout Board controls the inputs to the unit as well as

outputs for current mode, faults, and diagnostics. A status

LED and different combination of four LEDs for each fault are

provided for diagnostics. The Lockout Board Terminal (L) puts

out the number of corresponding 24VAC pulses to indicate the

Lockout condition on the Thermostat (if equipped and wired).

Startup/Random Start

The unit will not operate until all the inputs and safety controls

are checked for normal conditions. A ten to twenty second

random start delay is added at power up and whenever a Y1

call is received. This avoids multiple units from being energized

at the same time after events such as power loss or brown

outs.

Short Cycle Protection

A built-in five minute anti-short cycle (ASC) timer provides

short cycle protection ensuring that the compressor isn’t

damaged due to rapid cycling.

Test Mode

The Lockout Board allows the technician to shorten timing

delays for faster diagnostics by placing the DIP switch ‘TEST’

switch in the ON position (See ‘Settings’ section). It should be

moved back to OFF for normal operation after testing. The

status LED will not be illuminated during the TEST mode.

4-Way Valve Control

When 24Vac is applied to the O terminal on the field wiring

block, the controller energizes its O1 output to provide 24Vac

power to the reversing valve to switch the refrigerant circuit to

the cooling mode.

Changeover from heating to cooling can be achieved in two

ways:

1. A manual toggle switch to select the heating or the

cooling hydronic control (Aquastat), or.

2. A cooling thermostat which powers the coil of a single

pole/double throw relay to select the heating hydronic

control (normally closed contact) or the cooling hydronic

control (normally open contact).

Compressor Control

When 24Vac is applied to the Y terminal on the controller

wiring block, the controller decides, based on lockout and

anti-short-cycle periods, when to turn on the compressor

contactor. The CC output of the controller energizes the

contactor(s) until 24Vac is removed from the Y terminal or a

fault is detected.

Safety

The lockout board receives feedback signals for high pressure,

low pressure, load heat exchanger temperature, source

heat exchanger temperature, condensate overflow, and

hot gas temperature faults. Upon a continuous 10-second

measurement of all faults (except the high pressure) the

compressor operation is suspended. The high pressure fault is

tripped instantly. The different combination of LED(s) indicate

each temporary fault. Once the unit is locked out (see fault

retry below), the Lockout Board outputs a number of 24VAC

pulses equal to the numbered fault code. In lock out the unit

will not start until a soft or hard reset.

Low Pressure (LP)

If the low pressure switch is open continuously for 10 seconds,

the compressor operation will be interrupted and the control

will go into fault retry mode. At startup, the low pressure

switch monitoring is suspended for 30 seconds to avoid

nuisance faults. However, if the low pressure switch is open

before startup then the unit will not start upon receiving an Y1

call and will lock out instead.

Note: Flow switches are not equipped with this unit. A jumper

wire overrides this feature. A flow switch kit is available to add

on: Part Number: 28K053-05NN.

Flow Switch (FS)

Flow switches ensure the source and load water maintain

the minimum required flow rate. This ensures that pumps

are working and water connections remain intact. If the flow

switch is open continuously for 10 seconds, the compressor

operation will be interrupted with a FS fault. At startup, the

flow switch monitoring is suspended for 30 seconds to avoid

nuisance faults. The flow switches will also trip when the

water begins to freeze, providing additional protection.