4S-SERIES PRESSURE EXCHANGER ENERGY RECOVERY DEVICES

Energy Recovery, Inc.

13

ERI Document Number 80022-01-04

6.

Adjust the brine flow to balance the high- and low-pressure flows to the PX unit.

7.

After the PX unit and booster pump have run for 5 to 10 minutes and all air and gas has

been purged from the system, start the main high-pressure pump. The SWRO system

pressure will increase to the point where the permeate flow will equal the flow from the

main high-pressure pump. The noise level from the PX unit will increase. Small

variations in noise level and rotor speed are normal.

8.

Verify the high- and low-pressure flow rates. Adjust flows as necessary to achieve

balanced flow to the PX unit.

9.

Verify that brine reject pressure (LP OUT) is above minimum requirements.

6.2.2 Short Term (1-3 Days) System Shut Down Sequence

1.

Stop the main high-pressure pump.

2.

Wait until the system pressure drops below 400 psig (28 bar). Open a purge valve if

necessary to expedite depressurization.

3.

Stop the PX booster pump.

4.

Stop the seawater inlet supply pump.

6.2.3 Medium Term (4-14 Days) System Shut Down Sequence

1.

Feed the PX unit and SWRO system with fresh water. A feed pressure of 27 psi (1.9 bar)

is necessary to assure complete flushing.

2.

Make sure booster pump is operating. Run the system for 5 to 10 minutes until all the

seawater is purged.

3.

Stop the booster pump.

5.

Isolate the fresh water supply source.

6.2.4 Long Term (Over 2 Weeks) System Shut Down Sequence

If a plant is to be shut down for an extended period of time, the SWRO system including the PX

units must be thoroughly flushed with fresh water to remove any salt and precautions should be

taken to inhibit biological growth. The high-pressure and low-pressure sides of the PX unit must

be flushed separately. The low-pressure flush should flushed with fresh water through the

seawater feed line to the PX unit and to the brine drain. The high-pressure flush is typically

performed by circulating water through the PX unit and the membranes using the booster pump.

The PX units should receive a final flush with the same solution used to preserve the SWRO

membranes.

A minimum of 27 psi (1.9 bar) is required to feed the PX unit low-pressure inlet.

The fresh water flush will not occur without sufficient pressure.

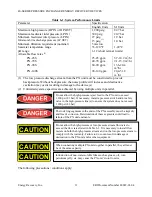

Continuous operation of the main high-pressure pump is not recommended during

the fresh water flush sequence, however momentary operation of the pump will

help purge seawater from the PX unit and membranes.

The main high-pressure pump should never be operated without the booster pump.

An interlock should be installed so that the high-pressure pump will automatically

shut down if the booster pump shuts down.

NOTE

NOTE

NOTE