6

Liquid Master® W-Series

English

WARNING

WARNING: Improper use or failure to follow instructions can result in explosive failure causing serious

eye or other injury.

For safe use of this product you must read and follow all instructions. Do not leave a

pressurized sprayer in the hot sun. Heat can cause pressure build-up resulting in possible explosion. Do not

store or leave solution in tank after use. Always wear goggles, gloves, long sleeve shirt, long pants and full foot

protection when spraying. Do not attempt to modify this sprayer. Replace

parts only with manufacturer’s original

parts.

Never spray flammable, caustic, acidic, chlorine, bleach or other corrosive solutions or heat,

pressure, or gas producing chemicals. Always read and follow chemical manufacturer’s instructions

before use with this sprayer as some chemicals may be hazardous when used with this sprayer.

CAUTION

•

PRE-USE CHECK:

Before each use check tightness of hose nut to be sure hose is securely attached to

the shut-off assembly. Ensure that all nozzle and wand connections are tight.

•

Do Not exceed a tank solution temperature of 120º F/ 49º C.

NOTE: The tank and hose may have residual water in it due to quality testing performed on the sprayer.

WARNING

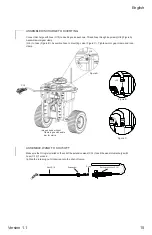

This sprayer is designed to operate with a Chapin 24V Lithium Ion battery ONLY. Any other batteries could

cause serious harm or injury to the operator and serious damage to the sprayer.

WARNING:

For safe operation, read this manual before using the charger. The battery pack is not fully charged

out of the carton. Before using the battery pack and charger, read the safety instructions below. Then follow

charging procedures outlined.

NOTE:

Remove battery and place in charger when not in use.

IMPORTANT SAFETY INSTRUCTION FOR BATTERY PACKS READ ALL

INSTRUCTIONS

•

DO NOT incinerate the battery pack even if it is severely damaged or is completely worn out.

The

battery pack can explode in a fire. Toxic fumes and materials are created when battery packs are burned.

•

DO NOT charge or use battery in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust.

Inserting or removing the battery from the charger may ignite the dust or fumes.

•

If battery contents come into contact with the skin, immediately wash area with mild soap and water.

If battery liquid gets into the eye, rinse water over the open eye for 15 minutes or until irritation ceases. If

medical attention is needed, the battery electrolyte for Lithium-Ion batteries is composed of a mixture of

liquid organic carbonates and lithium salts.

•

Contents of opened battery cells may cause respiratory irritation.

Provide fresh air. If symptoms persist,

seek medical attention.

WARNING: Burn hazard.

Battery liquid may be flammable if exposed to spark or flame.

•

Charge the battery packs only in

Chapin

chargers.

•

DO NOT splash or immerse in water or other liquids.

This may cause premature cell failure.

•

DO NOT store or use the tool and battery pack in locations where the temperature may reach or

exceed 105ºF (40ºC) (such as outside sheds or metal buildings in summer).

WARNING:

Never attempt to open the battery pack for any reason. If battery pack case is cracked or damaged,

do not insert into charger. Do not crush, drop or damage battery pack. Do not use a battery pack or charger that

has received a sharp blow, been dropped, run over or damaged in any way (i.e., pierced with a nail, hit with a

hammer, stepped on). Damaged battery packs should be returned to service center for recycling.

WARNING: Fire hazard. Do not store or carry battery so that metal objects can contact exposed battery

terminals.

For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc.,

with loose nails, screws, keys, etc.

Transporting batteries can possibly cause fires if the battery terminals inadvertently come in contact with

conductive materials such as keys, coins, hand tools and the like.

The US Department of transportation

Hazardous Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e.,

packed in suitcases and carry-on luggage) UNLESS they are properly protected from short circuits. So when

transporting individual batteries, make sure that the battery terminals are protected and well insulated from

materials that could contact them and cause a short circuit.

NOTE: Lithium-Ion batteries should not be put in

checked baggage.