CNGmass DCI

Wiring

Hauser

19

A0001135

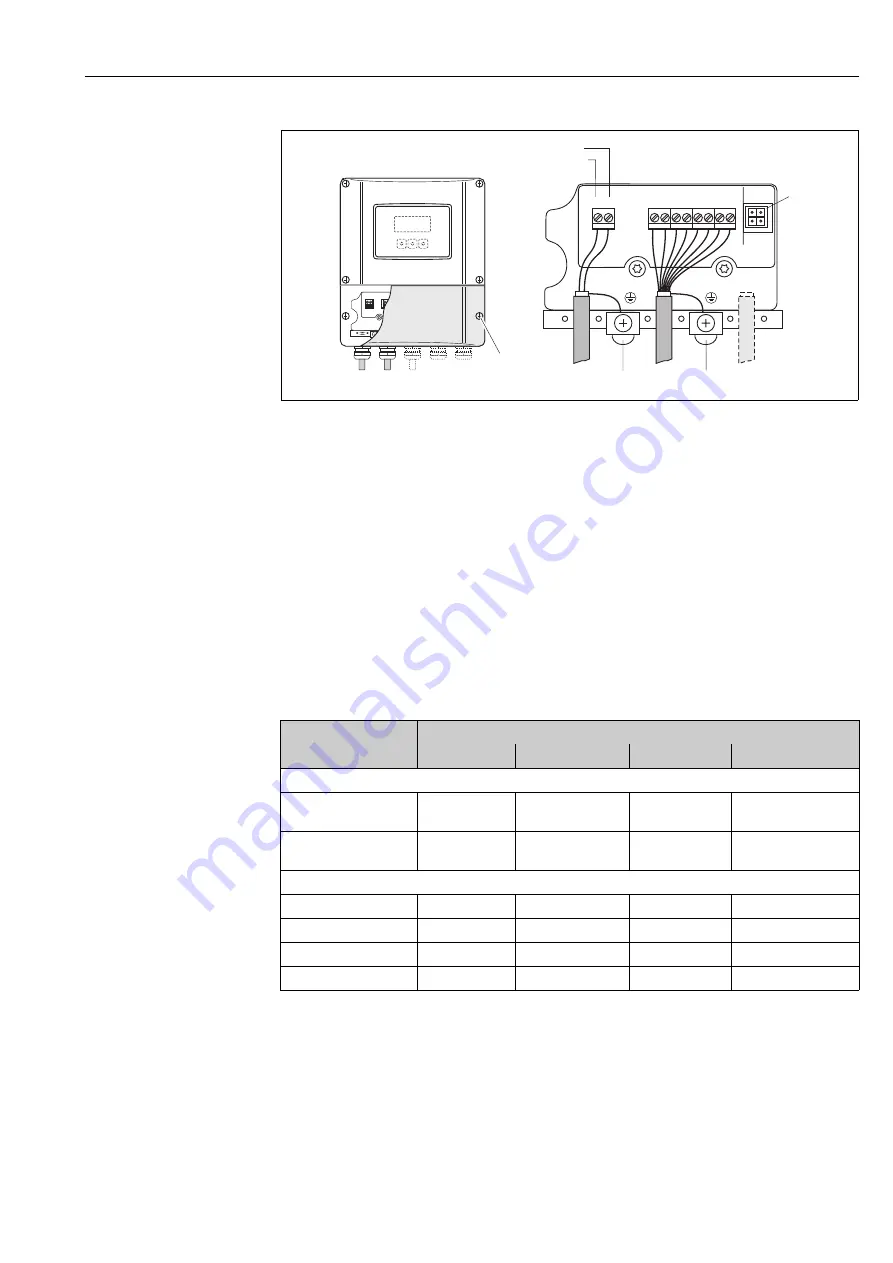

Fig. 13:

Connecting the transmitter (wall-mount housing), cable cross-section: max. 2.5 mm

2

(14 AWG)

2

a

Cable for power supply: 85 to 260 V AC, 20 to 55 V AC, 16 to 62 V DC

– Terminal No. 1: L1 for AC, L+ for DC

– Terminal No. 2: N for AC, L- for DC

b

Signal cable: Terminals No. 20 to 27

c

Ground terminal for protective ground

d

Ground terminal for signal cable shield

e

Service adapter for connecting service interface FXA193 (Fieldcheck, FieldCare)

f

Cover of the connection compartment

4.3.2

Terminal assignment

Electrical values for inputs

1

2

c

d

e

a

a

b

b

f

+

22

–

23

+

20

–

21

+

24

–

25

+

26

–

27

L1 (L+)

N (L-)

Terminal No. (inputs/outputs)

Order version

20 (+) / 21 (-)

22 (+) / 23 (-)

24 (+) / 25 (-)

26 (+) / 27 (–)

Fixed communication boards (permanent assignment)

8DF**-***********S

–

–

Frequency output,

Ex i, passive

Current output, Ex i,

active, HART

8DF**-***********T

–

–

Frequency output,

Ex i, passive

Current output, Ex i,

active, HART

Flexible communication boards

8DF**-***********D

Status input

Relay output

Frequency output

Current output, HART

8DF**-***********M

Status input

Frequency output 2

Frequency output 1 Current output, HART

8DF**-***********1

Relay output

Frequency output 2

Frequency output 1 Current output, HART

8DF**-***********2

Relay output

Current output 2

Frequency output

Current output 1, HART