Page 9 of 20

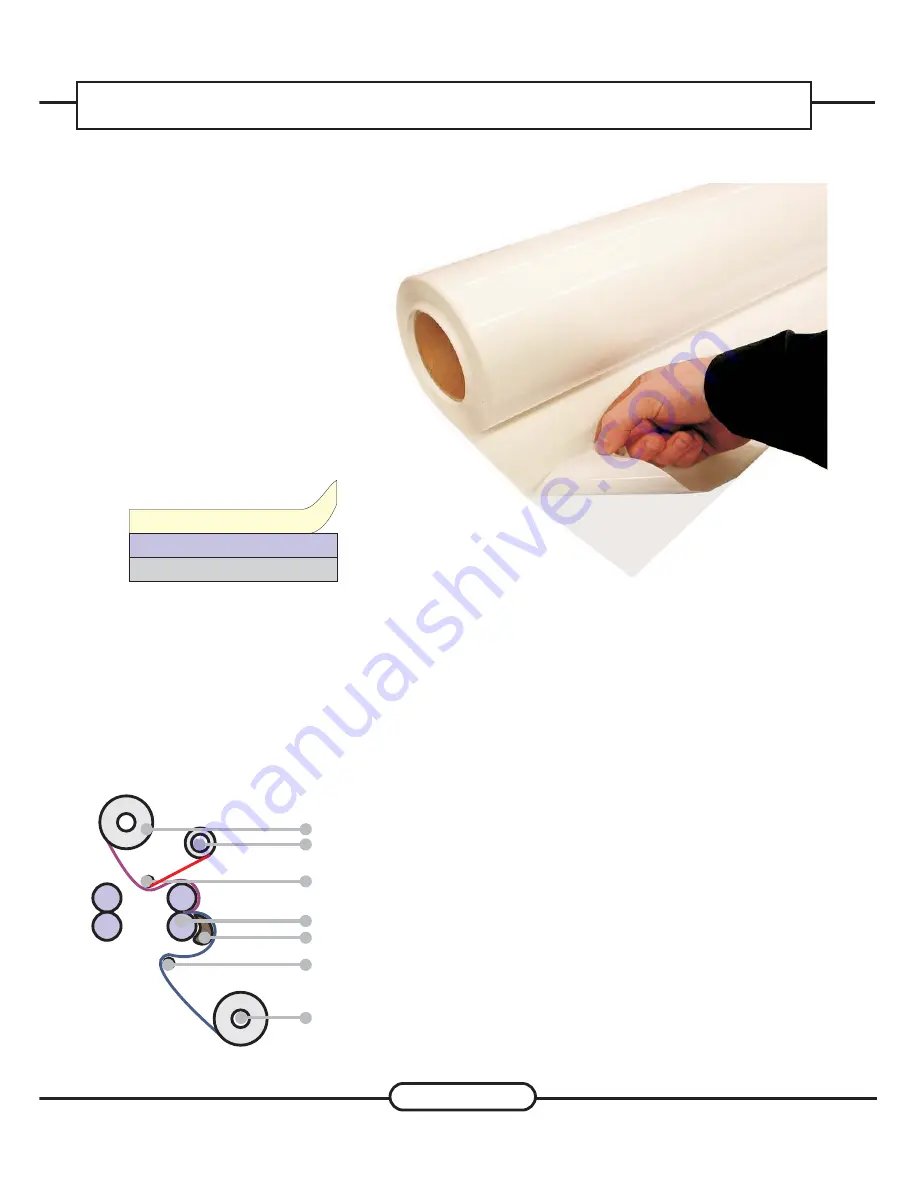

Pressure sensitive laminating - introduction

REQUIRES OPTIONAL TOP REWIND

Release Paper

Adhesive layer

Plastic layer

The theory - Pressure sensitive film

Cold or Pressure Sensitive laminating involves using a self adhesive

film, usually with a release paper. This has the advantage of

being able to stick to difficult to laminate items,

such as some inkjet prints or similar

media.

Laminating with pressure sensitive film

involves removing the protective

layer of release paper from the film,

and then pressing the adhesive layers

firmly to the item being laminated. This

firmly bonds the film to the surface of the

item, resulting in lasting protection.

Most laminating done with pressure sensitive

laminates is single sided, as the cost of double

sided lamination is expensive.

Underlay paper

Underlay is the term used to describe an inexpensive paper material which feeds into the machine

below the laminated item. Its sole purpose is to prevent the adhesive on the pressure sensitive

film coming into contact with the rubber rollers during single sided laminating.

Cheap paper or plastic of most types can be used. It should be wider than the pressure sensitive

film, and not easily stretched. When the laminated item is trimmed flush to the edges, the

underlay will fall off and can be discarded.

This illustrates how a cross

section of pressure sensitive

film would appear.

Release paper peeled back

to reveal adhesive.

This loading diagram illustrates the film

path, and the parts of the laminator.

Upper Supply roll

Underlay paper

Upper Idler Bar

Rewind core

Lower Roller

Heater Bar

Lower idler bar

Summary of Contents for Centaur

Page 1: ...Assembly Operators Manual ...