2

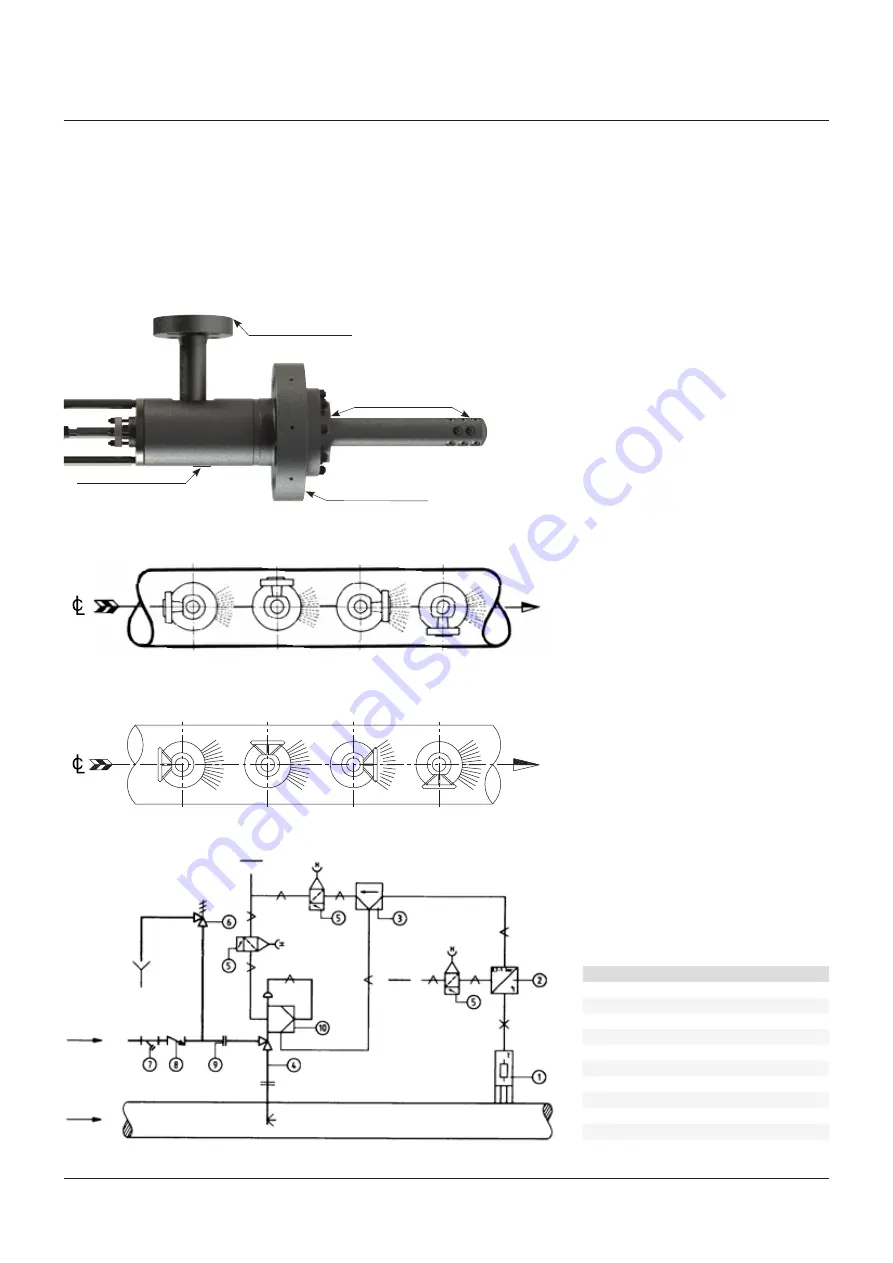

HWW HWN HWe HWs

Fp9

Fp12

Fp3

Fp6

FIgure 4

FIgure 3

Water flange positions

steam line

steam flow

Handwheel positions

steam line

steam flow

air

air

Water

steam

YArwAY

TemplowHT desuperHeaTer

InstallatIon and MaIntenance InstructIons

The minimum pipe run, required downstream

of the TemplowHT desuperheater, varies

with each individual application and would

be specified by Yarway at the enquiry stage.

This straight run is needed to prevent erosion

due to impingement of water droplets against

pipewalls, valves and fittings and is normally

item

Description

1

Temperature sensor

2

Temperature transmitter

3

Temperature controller

4

TemplowHT desuperheater

5

air filter regulator

6

safety relief valve

7

strainer

8

Check valve

9

Flange

10

e/p-positioner

FIgure 1 - Model 59/69/79

Check for damages

Identification plate

Check for damages

Check for damages

in the order of 4 to 6 meters, as a minimum (no

upstream straight length is normally required).

The distance from the TemplowHT desuperheater

to the temperature sensor is nominally 12 to

15 meters, although the distance specific to

the application would be advised by Yarway at

the enquiry stage. longer distances will ensure

that full evaporation of the water will take place

at lower steam velocities.

The temperature sensor should be located in

the upper half of the pipe, avoid branching of

the steam pipework between the TemplowHT

desuperheater and the sensor (see figure 4).