3

INSTALLATION

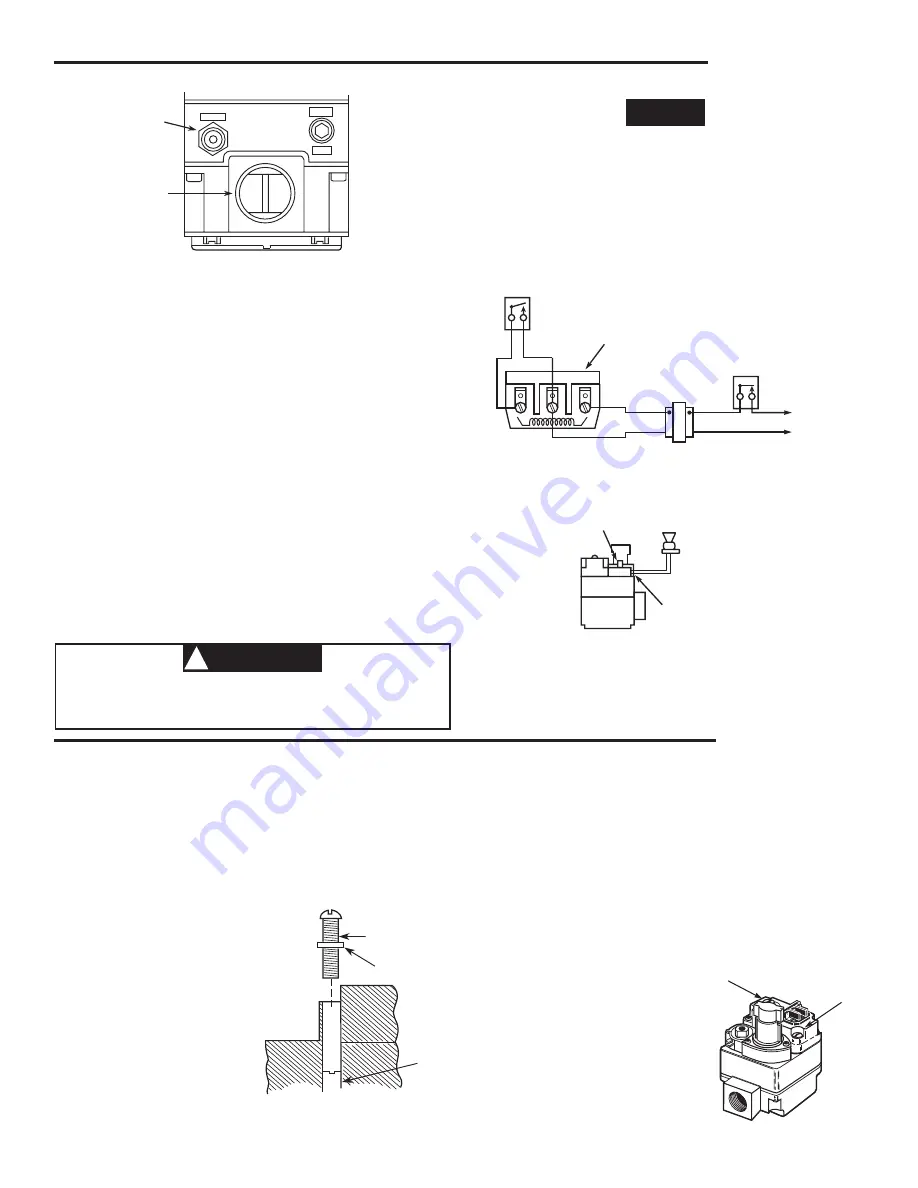

Pilot Gas

Outlet

Gas Outlet

PRESS

TAP

PILOT

Figure 3. Gas valve side view

THERMOCOUPLE CONNECTION

The thermocouple connection should be clean to ensure good

electrical contact.

Run the thermocouple nut into the power unit tapping as far as pos-

sible by hand. Then use a small wrench to set the nut with a

1

⁄

4

to

1

⁄

2

additional turn.

Do not overtighten

.

Connect leads from E.C.O. terminals to E.C.O. device on furnace.

Test E.C.O. device for continuity. If there is no continuity, power unit

will not hold in.

If the furnace does not have an E.C.O. device, use the jumper pro-

vided in the pack.

SYSTEM WIRING

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electrical power to system at main fuse or circuit

breaker box until installation is complete.

ENERGY CUT OFF (E.C.O.) CONNECTION

A five-function valve uses the 2 E.C.O. terminals that are connected

to the magnetic assembly where the thermocouple connects to the

36C valve line interrupter. An E.C.O. device is mounted in the furnace

near the limit control and a lead assembly is connected to the E.C.O.

terminals on the 36C valve.

THERMOCOUPLE

CONNECTION

E.C.O.

DEVICE

LEAD

ASSEMBLY

E.C.O. TERMINALS

Figure 5. Wiring for Energy Cut-Off (E.C.O.) connection

NOTE

All wiring should be installed in accordance with local and

national electrical codes and ordinances.

Always check that the electrical power supply used agrees with the

voltage and frequency shown on the gas control.

The typical wiring diagram shows only the terminal identification

and wiring hook up. Always refer to wiring instructions provided

by

Equipment Manufacturer for system hookup operation.

PRESSURE REGULATOR ADJUSTMENT

The pressure regulator has been factory adjusted (see control

for specific setting). Although additional adjustments will not

normally be necessary, you may adjust the regulator.

Do not

force the adjusting screw beyond the limits that it can

easily be adjusted.

1. Energize valve to ignite main burner.

2. Remove "Reg. Adj." cover screw (see fig. 7).

3.

To DECREASE outlet pressure

, turn the adjusting

screw (beneath the

cover screw) counter-

clockwise.

To IN-

CREASE outlet pres-

sure

, turn the adjust-

ing screw clockwise.

4. Replace the cover

screw. Cycle the valve

two or three times to

verify regulator setting.

Pilot Adjust

Cover Screw

Gasket

Pilot

Adjust

Screw

Figure 6. Pilot Flame Adjustment

OFF

PI

LO

T

ON

PILOT ADJUST

COVER SCREW

Figure 7. Pressure regulator adjustment

REGULATOR ADJUSTING

COVER SCREW

PILOT FLAME ADJUSTMENT

If the pilot flame is low and does not engulf the bulb of the

mercury flame sensor, the system will not energize the main

valve. If pilot gas pressure is too high, gas will sputter past the

ignition electrode, and may not ignite. High pilot gas pressure

may also cause the flame to lift off the burner, causing the

flame sensor bulb to sense "low" heat.

To adjust the pilot gas pres-

sure, remove the cover screw

(see fig. 6).

To REDUCE

pilot pressure

, turn the pilot

adjust screw (beneath the

cover screw) clockwise.

To

INCREASE pilot pressure

,

turn the pilot adjust screw

counterclockwise. Replace

and tighten cover screw.

ADJUSTMENT

GAS VALVE

TERMINAL PANEL

Figure 4. Wiring for 36C53

TH TH-TR

TR

LINE

HIGH

LIMIT

24 VAC

HOT

TRANSFORMER

THERMOSTAT

Figure 3. Gas valve side view

Figure 4. Wiring for 36C53

Figure 5. Wiring for Energy Cur-Off (E.C.O.) connection

Figure 6. Pilot flame adjustment

Figure 7. Pressure regulator adjustment