Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation

Parameters

Technical

data

Component

sizing

Diagnostics

Unidrive SP Regen Installation Guide

79

Issue Number: 2 www.controltechniques.com

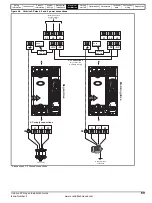

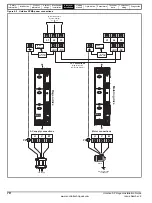

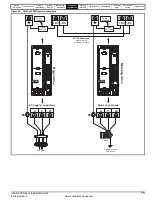

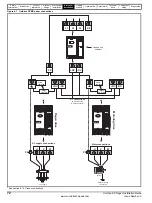

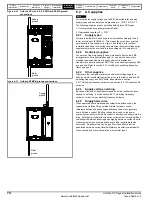

6.5.2 General requirements for EMC

Ground (earth) connections

The grounding arrangements should be in accordance with Figure 6-14,

which shows both drives mounted on a back-plate with or without an

additional enclosure.

Figure 6-14 shows how to manage EMC when using a shielded motor

cable, and indicates the clearances which should be observed around

the drive and related ‘noisy’ power cables by all sensitive control signals

/ equipment.

300mm

(12in)

±

DC bus connections

Metal backplate

safety bonded to

power ground busbar

Grounding

bar

Signal

cables

Use four core cable to

connect the motor to the drive.

The ground conductor in the

motor cable must be connected

directly to the ground terminal of

the drive and motor.

It must not be connected directly

to the power ground busbar.

The voltage present in the

wiring between the Regen

drive and regen inductor

is a source of radio

emission. These cables

should be kept as short as

possible. (I.e. The regen

inductor mounted as

close as possible to the

Regen drive.)

The DC connection between the

Regen and motoring drive carries

common mode high frequency

voltage comparable with the

output voltage from a standard

drive.

Screened cable should be used

with the screen connection

connected to a single power

ground busbar or low impedance

ground terminal inside the cubicle.

EMC filter

Regen

components

External

controller

0V PE

Screen and ground connections

should be followed as shown in

.

Electrical Installation

Reg

en drive

Motori

ng

drive

The incoming supply ground,

PE, should be connected to a

single power ground bus bar

or low impedance ground

terminal inside the cubicle.

This should be used as a

common 'clean' ground for all

components inside the cubicle.

If the control circuit 0V

is to be grounded, this

should be done at the

system controller only to

avoid injecting noise

currents into the 0V circuit

Do not place sensitive

(unscreened) signal circuits

in a zone extending

300mm (12”) all around the

drive, motor cable, input

cable from EMC filter

Figure 6-14 General EMC enclosure layout showing earth / ground connections

Summary of Contents for SP1201

Page 219: ......

Page 220: ...0471 0029 02 ...