Oxymitter 5000

E-2

Instruction Manual

IM-106-350, Rev 2.2

July 2008

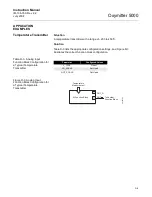

The block supports two forms of the PID equation: Standard and Series. You

can choose the appropriate equation using the FORM parameter. The

Standard ISA PID equation is the default selection.

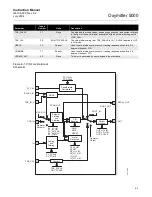

To further customize the block for use in your application, you can configure

filtering, feedforward inputs, tracking inputs, setpoint and output limiting, PID

equation structures, and block output action. Table E-1 lists the PID block

parameters and their descriptions, units of measure, and index numbers, and

Figure E-1 illustrates the internal components of the PID function block.

Table E-1. PID Function Block

System Parameters

Standard Out = GAIN

e

x

x

1

r

s

1

+

d

s

d

s

1

+

1 +

F

+

Series Out = GAIN

e

x

x

1

1

r

s

+

d

s

1

x

+

d

s

1

+

F

+

Where

GAIN: proportional gain value

r: Integral action time constant (RESET parameter) in seconds

s: laplac e operator

d: derivative action time constant (RATE parameter)

fixed smoothing factor of 0.1 applied to RATE

F: feedforward control contribution from the feedforward input (FF_VAL parameter)

e: error between setpoint and process variable

+

t

t

t

t

t

+

a

t

a

:

t

38730128

Parameter

Index

Number

Units

Description

ACK_OPTION

46

None

Used to set auto acknowledgment of alarms.

ALARM_HYS

47

Percent

The amount the alarm value must return to within the alarm limit before the

associated active alarm condition clears.

ALARM_SUM

45

None

The summary alarm is used for all process alarms in the block. The cause of

the alert is entered in the subcode field. The first alert to become active will

set the Active status in the Status parameter. As soon as the Unreported

status is cleared by the alert reporting task, another block alert may be

reported without clearing the Active status, if the subcode has changed.

ALERT_KEY

04

None

The identification number of the plant unit. This information may be used in

the host for sorting alarms, etc.

ALG_TYPE

74

None

Selects filtering algorithm as Backward or Bilinear.

BAL_TIME

25

Seconds

The specified time for the internal working value of bias to return to the

operator set bias. Also used to specify the time constant at which the integral

term will move to obtain balance when the output is limited and the mode is

AUTO, CAS, or RCAS.

BIAS

66

EU of OUT_SCALE

The bias value used to calculate output for a PD type controller.

BKCAL_HYS

30

Percent

The amount the output value must change away from the its output limit

before limit status is turned off.

BKCAL_IN

27

EU of OUT_SCALE

The analog input value and status from another block’s BKCAL_OUT output

that is used for backward output tracking for bumpless transfer and to pass

limit status.

BKCAL_OUT

31

EU of PV_SCALE

The value and status required by the BKCAL_IN input of another block to

prevent reset windup and to provide bumpless transfer of closed loop control.

Summary of Contents for Oxymitter 5000

Page 2: ......

Page 6: ......

Page 12: ......

Page 22: ...Oxymitter 5000 xii Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 42: ...Oxymitter 5000 1 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 62: ...Oxymitter 5000 2 20 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 74: ...Oxymitter 5000 4 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 78: ...Oxymitter 5000 5 4 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 94: ...Oxymitter 5000 7 6 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 140: ...Oxymitter 5000 9 22 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 184: ...Oxymitter 5000 B 2 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 204: ...Oxymitter 5000 D 14 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 222: ...Oxymitter 5000 E 18 Instruction Manual IM 106 350 Rev 2 2 July 2008 ...

Page 224: ...Instruction Manual IM 106 350 Rev 2 2 July 2008 Index 2 Oxymitter 5000 ...