3

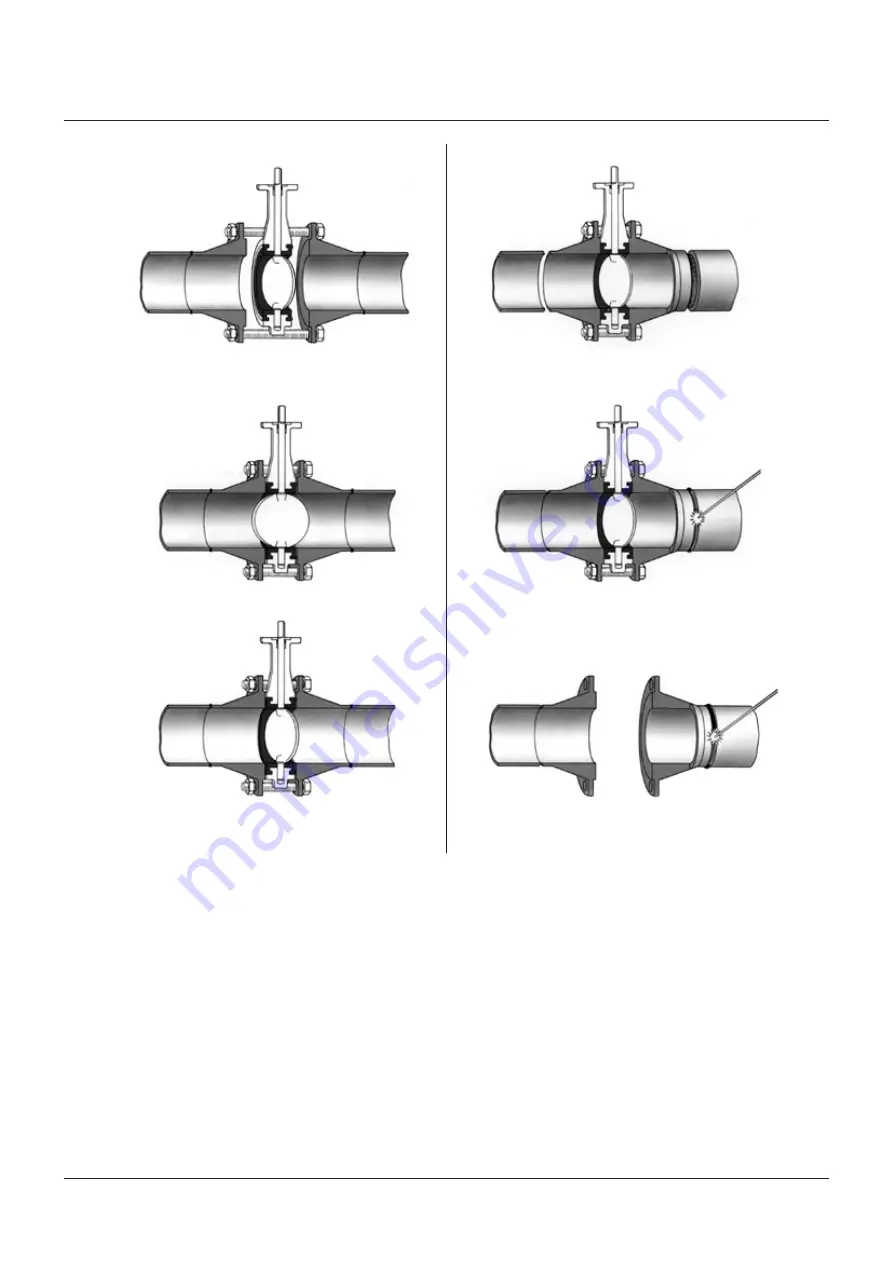

ExISTINg SYSTEm

NEW SYSTEm

1. spread the flanges with the adequate tooling.

insert some flange bolts to bear the valve.

1. Center a flange-valve-flange assembly between

the pipes.

2. Open the valve and remove the flange spreads.

2. tack weld the flanges to the pipes.

3. Close the valve clockwise, return to open position

and cross-tighten all bolting.

3. remove the valve and finish weld. install the valve

according to the procedure in the left column.

Installation in a new system (see diagrams)

it is common practice to use the valve to help in alignment of the flanges

prior to welding the flanges into the pipeline. in such cases, the following

instruction applies:

1. Open the valve until the disc is free of the seat but still contained

within the face to face of the valve.

2. align both mating flanges with the valve center line and secure in

position using the flange bolts.

3. Position the flange/valve/flange assembly in the pipeline.

4. tack weld the flanges to the pipeline.

5. remove the flange bolts and the valve.

6. Finish weld the flanges to the pipeline and allow to cool fully.

7. Follow the procedure for installation in an existing system.

KEYSTONE

Figure 990/991 ButterFly valves

InstallatIon, operatIon and maIntenance InstructIons

WarNINg

Do not finish weld the flanges to the pipeline with the valve still assembled

to the flanges as this will result in serious damage to the valve seat.