2

Europe, Middle East and

Africa Only

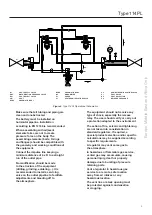

Type 114PL

Specifications

The Specifications section lists the specifications for Type 114PL Pressure Reducing System. Factory specification

are stamped on the nameplate fastened on the regulator at the factory.

Body Sizes and End Connection Styles

DN 25 / 1 NPS - CL600 Flanged

Outlet Pressure Range (P

d

)

(1)

1.0 to 18 bar / 14.5 to 261 psig

See Table 1

Maximum Allowable Operating Pressure (P

s

)

(1)

100 bar / 1450 psig

Maximum Obtainable Operating Pressure (P

u

)

(1)(2)

85 bar / 1233 psig

Construction Materials

Pilot Body:

Steel

Pilot Manometric Box BMP (spring case):

Steel

Pilot Manometric Box BMP (cover):

Steel

Flange and spacer:

Steel

Option

RPE (Electric Heater)

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

2. In extreme conditions (isopropanol, methanol)

Table 1

. Outlet Pressure Ranges

PNEUMATIC-LOADED

PILOT TYPE

SPRING-LOADED

PILOT TYPE

NOZZLE Ø

OUTLET PRESSURE RANGE (P

d

)

mm

In.

bar

psig

114

114E

4

0.16

1 to 4.8

14.5 to 69.6

071E

4

0.16

4.8 to 18

69.6 to 261

Principle of Operation

Type 114PL High-pressure Reducing and Low-flow

System uses inlet pressure as the operating medium,

which is reduced through the spring-loaded pilot to

load the pneumatic-loaded pilots’ cases.

When the outlet pressure (P

d

) drops, the motorization

pressure (P

m

) opens more the nozzles in the

pneumatic-loaded pilots supplying the required flow to

the downstream system.

Any excess motorization pressure on the actuator

diaphragm escapes downstream through the bleed

restriction in the pilot.

When the gas demand in the downstream system has

been satisfied, the outlet pressure (P

d

) increases. In

this case, the outlet pressure closes the nozzles in the

pneumatic-loaded pilots until reach the setting value.

Installation

▲

WARNING

Personal injury or equipment damage,

due to bursting of pressure-containing

parts may result if this system is

overpressured or is installed where

service conditions could exceed the

limits given in the characteristics

section and on the appropriate

nameplate or where conditions exceed

any rating of the adjacent piping or

piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits. Also, be

sure that installation is in compliance

with all applicable code and regulations.

Physical damage to the system can

break the pilot off the main valve,

causing personal injury and property

damage due to bursting of pressure-

containing parts. To avoid such injury

and damage, install the regulator in a

safe location. Only personnel qualified

through training and experience should

install, operate and maintain a regulator.

Before installation, make sure that there

is no damage to or debris in the system.