7

EN FVFA Series

North America

Only

4. If the flame arrestor sustained a burning event, thoroughly

inspect the element for any sign of damage. Replace the

element assembly if distorted crimps are visible, particularly

near the outer periphery of the flame element. Replace gaskets

if any damage is noted.

5. For best cleaning results, a high pressure sprayer with spray

wand should be used (1500 to 3000 psig / 103 to 207 bar) to

clean the entire element surface. The spray nozzle should be

held perpendicular to the surface being cleaned to maximize

spray media penetration into the element. Alternately spray

each side of the element surface until clean.

6. The cleaning interval should be governed by the amount and

type of particulate in the system to which it is installed and

must be determined by the user. To determine the maintenance

interval the user should check the element in the first few

months of operation to find how quickly particulate accumulates

in the cells.

Note

Under no circumstance should the element bank

be disassembled from its shell for cleaning

or replacement.

7. After cleaning, thoroughly inspect the element for damage. If

damaged, replace the element. Replace the element section as

a complete assembly.

Element Disassembly

▲

WARNING

Isolate gas supply and bring system to

atmospheric pressure to prevent ignitable gas

from flashing while performing maintenance.

1. Remove the top wing nuts.

2. Remove the hood and screen. It is not necessary to remove the

hex nuts located directly under the hood. These nuts are used

for positioning the hood.

△

CAUTION

The screen might have sharp edges. Use care

when handling.

3. Remove the upper nuts from the tensioning studs.

4. Remove the upper flange.

5. Remove the element assembly.

△

CAUTION

Some element assemblies are heavy and will

require the use of adequate equipment and

manpower to prevent injury.

Element Re-assembly

1. Thoroughly clean the gasket sealing faces being careful not to

damage the sealing surface. Lightly grease one side of a new

gasket and place it in the machined recess of the interior flange

on the conical sections and in the upper flange.

2. Replace the flame element assembly with a new assembly or

properly cleaned and inspected existing unit.

3. Re-assemble in the reverse order of disassembly.

4. Tighten the tensioning studs as detailed below:

△

CAUTION

Excessive or uneven torquing can cause

permanent damage to gaskets and housing.

Tools/Supplies Required:

• Torque wrench appropriate for the specified torque.

• Socket wrenches of the proper size to fit the hex nuts

being tightened.

• Molydisulfide based lubricating paste. Molykote

®

G-n

or equivalent.

• Brush suitable for applying lubricant to the studs.

• Wiping rags necessary for the clean-up of excessive lubricant.

Procedure:

1. Use studs and nuts that are free of visible contamination

and corrosion.

2. Apply lubricant to the threads of the stud protruding outboard

of the interior flanges and to the face of the hex nuts which

will contact the flange.

3. Assemble the nuts to the studs such that the amount of thread

extending outboard beyond the nut is approximately equal on

both ends.

4. Tighten the nuts to the values shown in Table 5 following the

designated sequence, repeating the sequence as shown.

Flange pattern tightening sequences are shown in Figure 5.

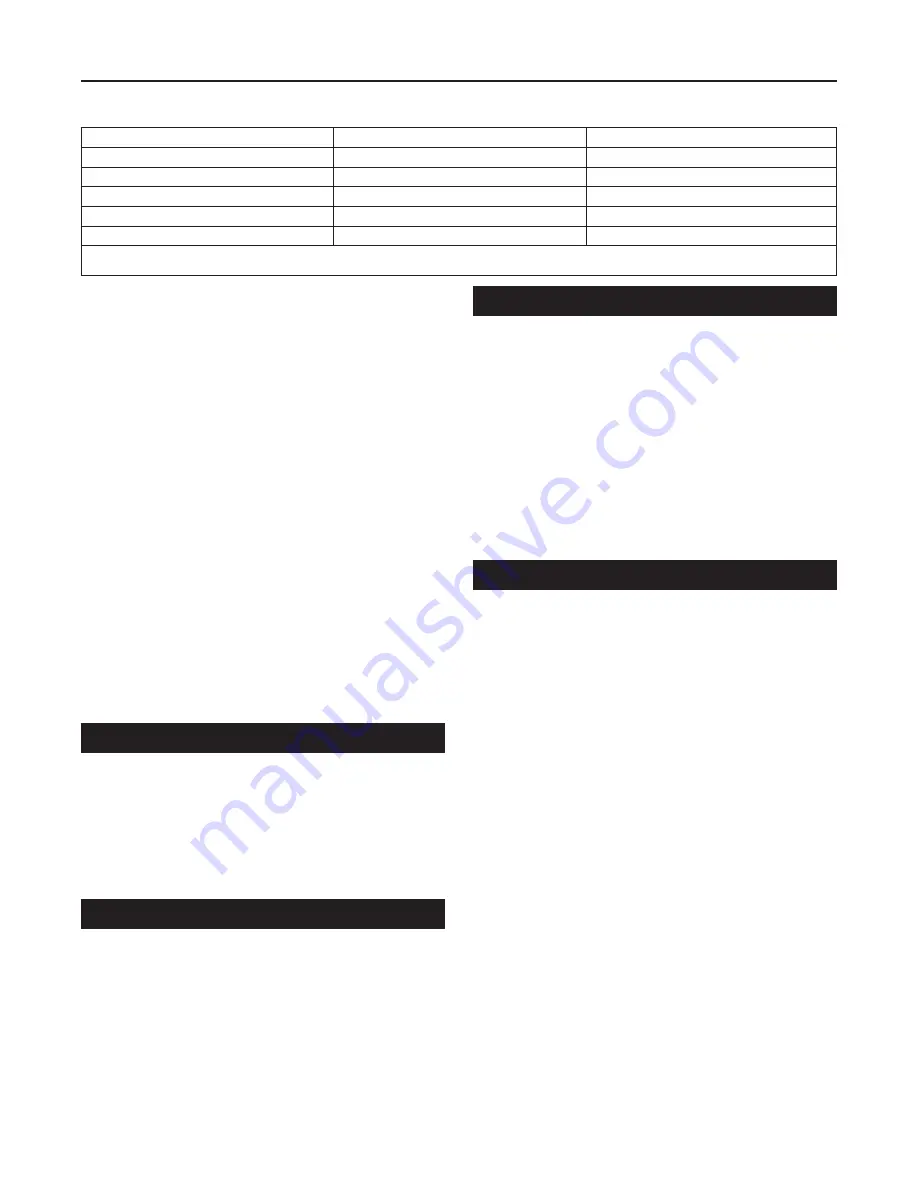

Table 6.

Torque

Correction Factors for Common Lubricants

DESCRIPTION

COEFFICIENT OF FRICTION

MULTIPLY TORQUE VALUE IN TABLE 6 BY

Machine Oil

f = 0.15

1.00

API SA2 Grease

f = 0.12

0.80

Nickel Based Lubricant

f = 0.11

0.73

Copper Based Lubricant

f = 0.10

0.67

Heavy-Duty Lubricating Paste

f = 0.06

0.40

NOTE: Carbon steel element assembly fasteners are provided with a low friction polymer coating. No additional lubrication should be required. When stainless steel fasteners are

provided, lubrication is recommended to reduce tightening torque and to prevent potential galling.

Molykote

®

G-n is a mark owned by Dow Corning Corporation.