AGL_HP_ST_ZHK1P_EN_Rev00

13

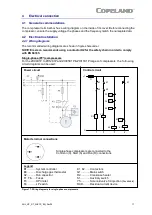

Figure 12: Sketch of discharge gas temperature protection for compressors with external sensor

For compressors ZHI18K1P and ZHI23K1P tandem-ready BOM 477 and f or compressors

ZHI27K1P to ZHI46K1P, the maximum discharge gas temperature is 135°C. These c ompres sors

are equipped with a NTC-temperature sensor in the top cap

– see

Figure 13

. This sensor

measures the discharge gas temperature in the top cap and must be connected to the cont roller,

eg, EXD TEVI (contact Emerson for more information). The controller has to stop the compressor

when the maximum discharge gas temperature is exceeded.

Figure 13: NTC sensor in top cap and resistance values for compressors ZHI18K1P and ZHI23K1P tandem ready

BOM 477 and ZHI27K1P to ZHI46K1P

In case the NTC top cap sensor shown in

Figure 13

has to be replaced please refer to t he S pare

f or the replacement kit with all

needed parts.

Please f ollow instructions hereunder:

▪

Remove the existing thermally conductive compound

f rom the thermal well.

▪

Dispense 0.75-1 cm

3

of thermally conductive compound

into the bottom of the thermal well.

▪

Clean any debris, grease or dirt f rom the upper cap

surf ace outside the thermistor tube opening along with the inside

tube surf ace. If the areas shown are not clean, the silicone

sealant will not adhere to the compressor.

▪

Apply a 5 mm bead of silicone sealant (Copeland ident

nr 8413046) on the thermistor in areas indicated.

▪

Af ter installation, the thermistor must be flushed with t he

top cap on, and the seal must be watertight.

Figure 14: Replacement of the NTC top cap sensor

Discharge gas temperature protection is the "f all-back" f or f ailure of the system control. It is

essential that proper control of both the evaporating and condensing pressures and the superheat

is maintained and has the ability to cope with all likely conditions and hig h lo ads. Reliance o n

protectors will cause inadequate system performance and short cycling.

Temperature

in °C

Resistance

in K

Ω

Temperature

in °C

Resistance

in K

Ω

-40

2889.60

80

10.79

-30

1522.20

90

7.87

-20

834.72

100

5.85

-10

475.74

110

4.45

0

280.82

120

3.35

10

171.17

130

2.58

20

107.44

140

2.02

25

86.00

150

1.59

30

69.28

160

1.25

40

45.81

170

1.01

50

30.99

180

0.83

60

21.40

190

0.68

70

15.07

-

-

Spring coil