C6.3.2/0416-0716/E

13

4

Electrical connection

4.1 General recommendations

The compressor terminal box has a wiring diagram on the inside of its cover. Before connecting

the compressor, ensure the supply voltage, the phases and the frequency match the nameplate

data.

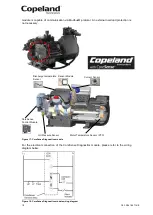

The knockouts have to be removed before the electrical glands can be installed. First make sure

that the terminal box is closed with the terminal box cover. We recommend to use a subland

twist driller to avoid any damage to the box while removing the knockouts.

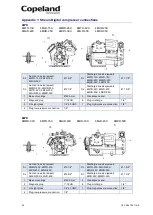

Figure 12

4.2 Electrical installation

All compressors can be started Direct-on-line.

The position of bridges required for Direct-on-line start (depending on type of motor and/or mains

voltage) is shown in Chapter 4.3 "Wiring diagrams".

4.2.1 Part-winding motors (YY/Y)

– Code A

Part-winding motors contain two separate windings (2/3 + 1/3) which are internally connected in

star and operated in parallel. You cannot change the voltage by changing the electrical

connections as these motors are only suitable for one voltage.

The first part winding, ie, the 2/3 winding on terminals 1-2-3, can be used for part-winding start

(remove the bridges!). After a time delay of 1 ± 0.1 seconds the second part winding, ie, the 1/3

winding on terminals 7-8-9, must be brought on line.

4.2.2 Star / Delta motors

(Y/∆) – Code E

Star / Delta motors are

interchangeable for star (Y) or delta (∆) operation by means of bridges.

They are suitable for two voltages, eg, 230V in delta, 400V in star connection. If the supply

voltage and the nominal voltage of the motor in ∆-connection are identical, the star connection

motor can also be used for starting (remove the bridges!).

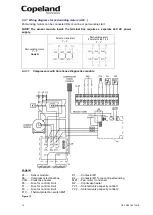

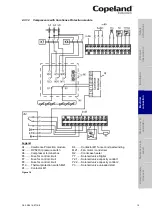

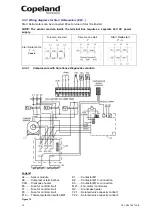

4.3 Wiring diagrams

The position of the jumpers in the terminal box and the recommended wiring diagrams are

shown in

Figures 13 to 16

.

S

afet

y

in

struct

ion

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Dismant

ling

&

d

ispo

sa

l

Twist driller