4

4.

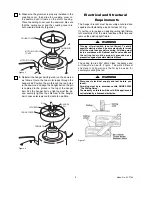

Remove the hanger ball by loosening the setscrew

in the hanger ball until the ball falls freely down the

downrod (Figure 3). Remove the pin from the

downrod, then remove the hanger ball. Retain the

pin and hanger ball for reinstallation in Step 9.

5.

Separate, untwist and unkink the two motor leads,

then route them through the hanger ball/downrod

assembly and seat the downrod in the motor

coupler (Figure 4).

6.

Align the clevis pin holes in the downrod with the

holes in the motor coupler. Install the clevis pin and

secure with the hairpin clip (Figure 4). The clevis

pin must go through the holes in the motor coupler

It is critical that the clevis pin in the motor coupler is

properly installed and the setscrews securely

tightened. Failure to verify that the pin and

setscrews are properly installed could result in the

fan falling.

7.

Install two setscrews (previously removed in

Step 2) in the motor coupler (Figure 4). While

pulling up on the hanger ball, securely tighten both

setscrews.

MOTOR COVER

M5 EXTERNAL TOOTH

LOCKWASHER (3)

M5 x 10mm PAN HEAD

SCREW (3)

Figure 2

PIN

HANGER

BALL

SETSCREW

DOWNROD

Figure 3

Assembly Instructions

CAUTION: The blade assemblies must be

mounted on the motor assembly so that the

raised lip edge is facing up.

1.

Rotate the motor hub so the notched area is above

the screw hole in the motor hub. Install one blade

assembly on the top of the motor assembly using

two M6 x 12mm pan head screws and two M6

lockwashers (supplied) (Figure 1). Repeat this

procedure for the remaining two blade assemblies.

Figure 1

M6 x 12mm PAN HEAD

SCREW

M6 LOCKWASHER

REMOVE

SETSCREW (2)

REVERSING SWITCH

MOTOR ASSEMBLY

FLAT AREA OF

MOTOR HUB

BLADE

ASSEMBLY

Model No.: ACF765

2.

Remove the two setscrews from the top of the

motor coupler (Figure 1). Retain the setscrews for

future use.

3.

Route the two motor leads through the center hole

in the motor cover. Place the motor cover over the

motor by aligning the reversing switch hole in the

cover over the reversing switch as shown in Figure

2. Secure by installing three M5 x 10mm pan head

screws and three M5 external tooth lockwashers

(supplied) (Figure 2).

It is critical that the clevis pin in the motor coupling

is properly installed and the setscrews securely

tightened. Failure to verify that the pin and setscrews

are properly installed (as shown in Figure 4) could

result in the fan falling.

WARNING

MOTOR COVER

REPLACE

SETSCREW (2)

HAIRPIN

CLIP

DOWNROD

CLEVIS

PIN

MOTOR

COUPLING

Figure 4