Flange Size and Rating

MAX PRESSURE

PSIA (kPaA)

Burn Time

Lowest

MESG

Gas Group

Direction of Flow

Serial Number

BI-DIRECTIONAL

Date of Manufacture

Customer Tag Number

WARNING: THIS DEVICE MUST BE PERIODICALLY

SERVICED FOR CONTINUED SAFE OPERATION

EU-Type Examination Certificate

NoBo No.

EN No.

ISO 16852

FLAME ARRESTORS HAVE INSTALLATION AND APPLICATION LIMITS.

TYPE DESIGNATION IN ACCORDANCE WITH ISO 16852.

FLAME ARRESTORS HAVE INSTALLATION AND APPLICATION LIMITS.

TYPE DESIGNATION IN ACCORDANCE WITH ISO 16852.

3

Model 2400

North America

Only

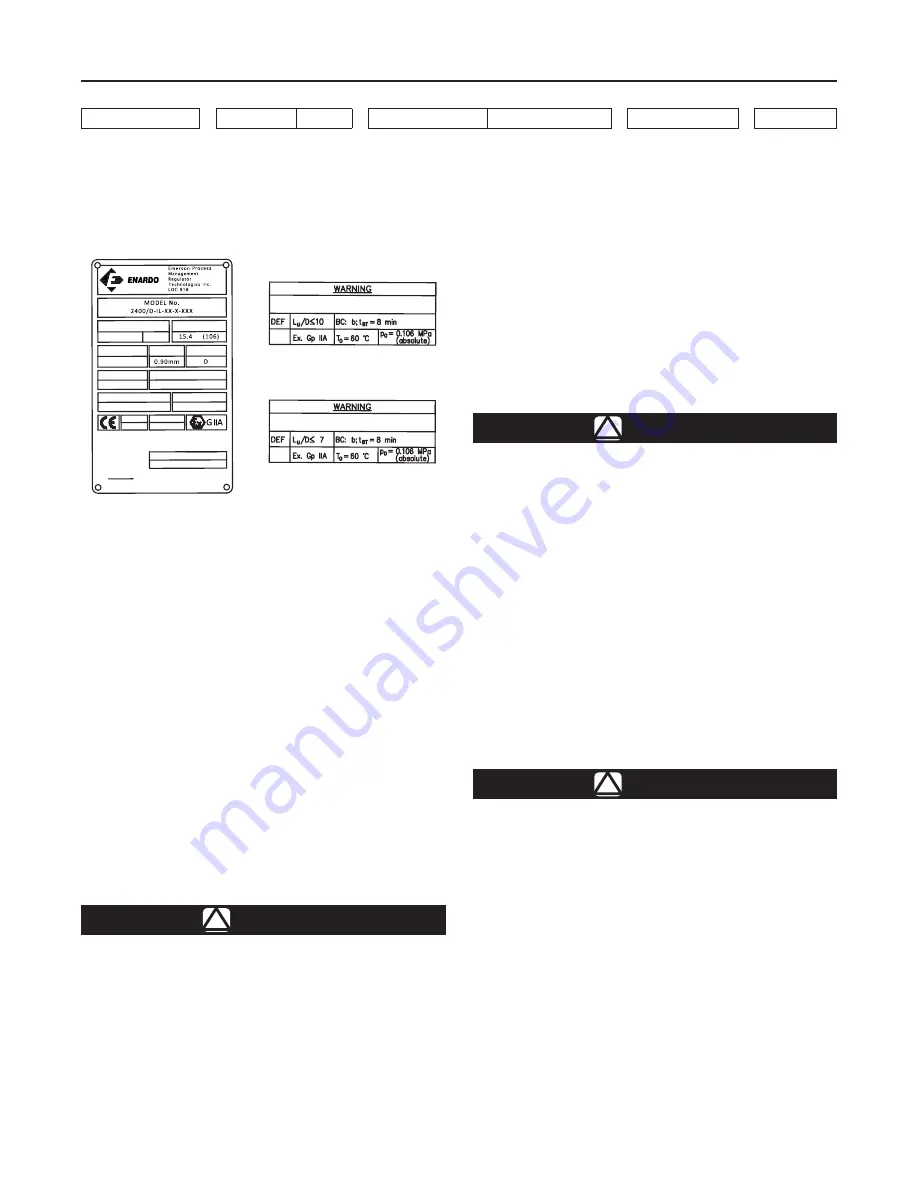

Figure 2

. Model 2400 In-line Duct Flame Arrestor Model Number

2400

/

IIA

- IL

-

C

4

-

A

-

046

CONNECTION SIZE

IEC

GAS GROUP

IN-LINE

SERIES

HOUSING MATERIAL

CELL MATERIAL

HOLE PATTERN

CRIMP

DESIGNATION

2400 = 24 in.

IIA

C = Carbon steel

4 = 304 Stainless steel

6 = 316 Stainless steel

H = Hastelloy

®

4 = 304 Stainless steel

6 = 316 Stainless steel

H = Hastelloy

®

A = ASME CL150

B = DIN PN10

C = DIN PN6

D = Standard

E = Other

046

059

into the unprotected side of the flame arrestor

assembly in order that the flow of explosive

vapors be stopped within t

bt

/2 (4 minutes) in

the event of an elevated temperature relative

to normal operating conditions. Bypassing,

sufficient diluting or inerting are measures

equivalent to stopping the flow.

Stabilized burning is steady burning of a flame stabilized at,

or close to, the flame arrestor element. This flame arrestor

has been tested for the time it takes for a stabilized flame,

at greatest heat saturation conditions, to heat the arrestor

element above the auto-ignition temperature of the process

gas stream resulting in flame propagation through the

arrestor. The short time burn rating is shown on the product

warning plate. Stabilized burning after ignition creates

additional hazards in applications where there could be

a continuous flow of the flammable mixture towards the

unprotected side of the flame arrestor.

Installation

!

WARNING

Always ensure that the system is at

atmospheric pressure and there is no ignitable

gas that could flash when installing this unit.

Flow Direction

The Model 2400 In-line Duct Flame Arrestor is bi-directional,

however, the temperature sensor must be located on the

unprotected (hot) side of the arrestor.

Hastelloy

®

is a mark owned by Haynes International, Inc.

Figure 3

. Product Marking Plates

Example Nameplate

Example Warning Plate 059 Option

Example Warning Plate 046 Option

Pipe Connections

The Model 2400 In-line Duct Flame Arrestor is fitted with

plate flanges with ANSI, DIN or custom bolting patterns

which require the use of full faced gaskets. Do not use ring

gaskets for the installation since excessive distortion of the

plate flanges can occur.

Pipe Length

!

WARNING

Do not exceed the maximum L/D pipe length

rating (L

u

) of the flame arrestor. If flame

propagation occurs at a distance greater

than the L/D rating of the flame arrestor,

the flamer arrestor could be ineffective in

stopping the flame propagation.

Extended lengths of pipe allow the flame to advance into

more severe states of flame propagation including high

pressure deflagrations or detonations. All Flame Arrestors

included in this series should be installed in accordance with

Table 1.

L

u

, expressed as a multiple of pipe diameters, is the

allowable length of pipe between the flame arrestor and

the ignition source without bends or other turbulence

causing devices.

Bends and/or Flow Obstructions

!

WARNING

No instrument, tubing or other device

whatsoever shall circumvent the flame

arrestor in such a manner to allow a flame

path to exist around the flame element

of the arrestor. When instrumentation is

installed in such a manner that it creates a

path circumventing the flame element of an

arrestor, measures must be taken to prevent

passage of flame through the instrumentation

device and/or system. Instrumentation must

be capable of withstanding the maximum

and minimum pressures and temperatures to

which the device may be exposed.

Bends in piping, pipe expansions, and/or contractions,

valves, orifice plates or flow obstructing devices of any kind

contribute to turbulent flow. Turbulent flow enhances mixing

of the combustible gases, greatly increasing the combustion

intensity. This can result in increased flame speeds, higher