DOC EATDS60S1P

6

Revision 08/19/20

Work Stations

Putting the Tool into Service

Safety Information

The tool is intended to be operated as a hand held tool. It is

always recommended that the tool be used when standing

on a solid floor. It can be in any position but before any such

use, the operator must be in a secure position having a firm

grip and footing and be aware that the tool can develop a

torque reaction. See the section “Safety Information”.

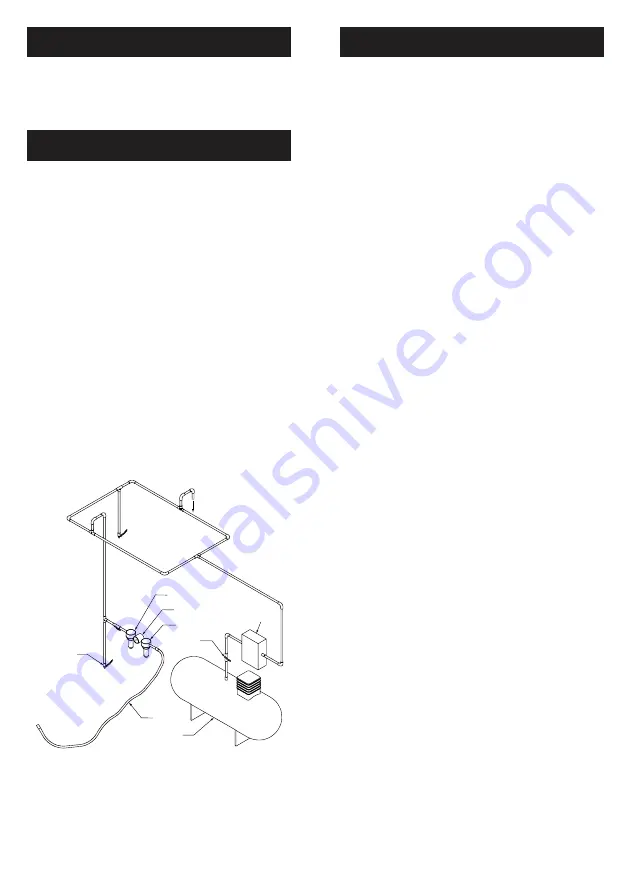

Use a clean lubricated air supply that will give a measured

air pressure at the tool of 90 psig (6.2 bar) when the tool is

running with the lever fully depressed. It is recommended

to use an approved 3/8 in. (10 mm) x 25 ft (8 m) maximum

length airline. It is recommended that the tool be connected

to the air supply as shown in Figure 1.

Do not connect the tool to the airline system without incorpo-

rating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that

an air filter, regulator and lubricator (FRL) be used as shown

in Figure 1 as this will supply clean, lubricated air at the

correct pressure to the tool. Details of such equipment can

be obtained from your supplier. If such equipment is not used

then the tool should be manually lubricated

To manually lubricate the tool, disconnect the airline and put

2 to 3 drops of suitable pneumatic motor lubricating oil such

as Fuji Kosan FK-20, Mobil ALMO 525 or Shell TORCULA®

32 into the hose end (inlet) of the machine. Reconnect tool to

the air supply and run tool slowly for a few seconds to allow

air to circulate the oil. If the tool is used frequently, lubricate

it on a daily basis or lubricate it if the tool starts to slow or

lose power.

It is recommended that the air pressure at the tool be 90 PSI

(6.2 Bar) while the tool is running so the maximum RPM is not

exceeded. The tool can be run at lower pressures but should

never be run higher than 90 PSI (6.2 Bar). If run at lower pres-

sure the performance of the tool is reduced.

Closed Loop Pipe System

Sloped in the direction

of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Figure 1

1) Read all instructions before using this tool. All operators

must be fully trained in its use and aware of these safety

rules. All service and repair must be carried out by

trained personnel.

2) Never direct air at yourself or anyone else.

3) Install air fitting into inlet bushing of tool.

4) Always remove the air supply to the tool before fitting,

adjusting or removing the abrasive/accessory.

5) Always wear required safety equipment when using this

tool.

6) When operating always place the tool on the work then

start the tool. Always remove the tool from the work

before stopping. This will prevent gouging of the work

due to excess speed of the abrasive/accessory.

7) Always adopt a firm footing and/or position and be aware

of torque reaction developed by the tool.

8) Use only correct spare parts.

9) Always ensure that the workpiece is firmly fixed to pre

-

vent its movement.

10) Check hose and fittings regularly for wear. Do not carry

the tool by its hose; always be careful to prevent the tool

from being started when carrying the tool with the air

supply connected.

11) Dust can be highly combustible. Keep working area

clean.

12) Dust from some work processes can cause cancer, birth

defects or other respiratory diseases. Risk assessment

of these hazards and implementation of appropriate

controls is essential.

13) Direct the exhaust so as to minimized disturbance of dust

in a dust filledenvironment

14) Do not operate the tool in explosive atmospheres, such

as in the presence of flammableliquids, gases, or dust.

The abrasives are able to create sparks when working

material, resulting in the ignition of the flammabledust

or fumes.

15) Do not exceed maximum recommended air pressure.

Use safety equipment as recommended.

16) The tool is not electrically insulated. Do not use where

there is a possibility of coming into contact with live

electricity, gas pipes, water pipes, etc. Check the area of

operation before operation.

17) Take care to avoid entanglement with the moving parts

of the tool with clothing, ties, hair, cleaning rags, etc. If

entangled, it will cause the body to be pulled towards the

work and moving parts of the machine and can be very

dangerous.

18) Keep hands away from rotating or reciprocation acces-

sories, spindles or other moving parts during use.

19) If the tool appears to malfunction, remove from use im-

mediately and arrange for service and repair.

20) Do not allow the tool to free speed without taking precau-

tions to protect any persons or objects from the loss of

the abrasive/accessory.

21) Do not allow tool to free run for an extended period of

time as this will shorten its life.