EAL - EAML

58 F - 63 F / G

INSTALLATION INSTRUCTIONS

© Copyright 2020 Eltra S.p.a. Unipersonale. All rights reserved.

All informations in this catalog are subject to change without notice.

Eltra takes no responsibility for typographic errors. For the terms of sales please check the website www.eltra.it.

Function

Cable colour

M12 5 pin

connector

*M12 8 pin

connector

+V DC

red

2

2

0 V

black

3

3

Vout / Iout

green

1

1

Iin

yellow

/

6

BEGIN

white

4

4

END

brown or grey

5

5

shield

housing

housing

ELECTRICAL CONNECTIONS

Complete documentation available on www.eltra.it

This device must be supplied by a Class 2

Power source or Limited Voltage / Current Circuit

Input Voltage: + 30V DC max

Input Current: 0.5A max

Teach-in procedure with SET button

• press SET button (at least 3 sec) -> the encoder enters into teach in procedure

(led B (GREEN) / led A (RED) on)

• keep pressed SET button (at least 3 more sec, 6 sec total) -> teach in procedure confi rmed

(led B (GREEN) / led A (RED) fl ashing 2 Hz frequency), 1 min timeout

• rotate the encoder shaft to initial position

• press SET button -> initial position set

(led B (GREEN) on / led A (RED) fl ashing), 10 min timeout

• rotate the encoder shaft to end position

• press SET button -> end position set

(led B (GREEN) / led A (RED) fl ashing 4 times (1,5 Hz frequency))

• led B (GREEN) on -> user parameters set

To reset to factory default (1 turn EAL - 15 turns EAML) press SET button at least 10 seconds

(led B (GREEN) / led A (RED) alternate fl ashing) -> led A (RED) on

Teach-in procedure with BEGIN/END inputs

• rotate the encoder shaft to start position

• set BEGIN input on high level (pulse) -> led B (GREEN) on / led A (RED) fl ashing (10 min timeout)

• rotate the encoder shaft to end position

• set END input on high level (pulse) -> end position set

(led B (GREEN) and led A (RED) fl ashing 4 times (frequency 1,5 Hz))

• led B (GREEN) on -> user parameter set

To reset to factory default (1 turn EAL - 15 turns EAML) set BEGIN / END inputs on high level simultaneously

(led B (GREEN) / led A (RED) alternate fl ashing) -> led A (RED) on

Led A (RED)

Led B (GREEN)

Meaning

on

off

normal operation / default parameters

off

on

normal operation / user parameters

on

on

entering teach-in

fl ashing

fl ashing

teach-in confi rmed / frequency 2 Hz

fl ashing

on

encoder start position set, wait for end position

fl ashing

fl ashing

SET button pressed for at least 10 sec

reset to factory default / alternate fl ashing

The leds on the encoder cover are useful to understand operating status of the product as show on below

table:

Overrun values outside programmed travel POS1 and POS2 are equally splitted respect minimum and

maximum output value with approximation to the next integer.

TEACH IN PROCEDURE

OVERRUN

LED INDICATION

SAFETY ADVICES

• The transducer must be used in observance of its specifi cations. The transducer is a precision measuring

instrument and it is not a safety device.

• The personnel charges in mounting and commissioning of the device must be qualifi ed and carefully

follow installation instructions. It is strongly recommended to avoid any mechanical or electrical

modifi cation for safety reasons. The warranty will lose in case of any modifi cations.

• Don’t expose the device to stresses or impacts in order to ensure the correct functioning.

• Make sure that the mechanical coupling of the transducer shaft is designed with the appropriate elastic

couplings, especially in the case of excessive axial or radial movements.

• The mechanical coupling between motor and trasducer shaft has to be made with appropriate elastic

couplings, especially in the case of excessive axial or radial movements.

• Check the operating environment is free from corrosive agents (acids, etc.) or substances that are not

compatible with the device and with its IP rating.

• Check the connection of the device to the ground; if necessary, provide an additional external connection.

• Products with variant code (a number or combination of numbers after “.”) may have different mechanical,

electrical or connections from standard product. Please refer to the additional documentation.

• Installation and wiring must be performed by trained personnel in a POWER-OFF condition.

• To prevent short-circuits, insulate unused wires at different lengths; do not use unused pins on the

connector.

• Before switching on, verify the voltage range applicable to the device.

• Place power and signal cables in order to avoid capacitive or inductive interferences that may cause

malfunction of the device. Place also transducer cable far from power lines or any other cable with high

noise levels.

• The user who integrates the transducer in his appliance must observe CE regulations and he is responsible

for the CE marking of the end machine/device.

• The malfunctions due to failure to observe these usage and installation precautions will loose the

warranty.

• Eltra considers itself free from any liability for damages or injuries due to non-observance of these

directives.

M12 connector (8 pin)

M12 A coded

solder side view FV

M12 connector (5 pin)

M12 A coded

solder side view FV

* with Q current ouput

Position

* not included

** not included, see P/N 41890426

this page intentionally left blank

this page intentionally left blank

this page intentionally left blank

Analogue output value

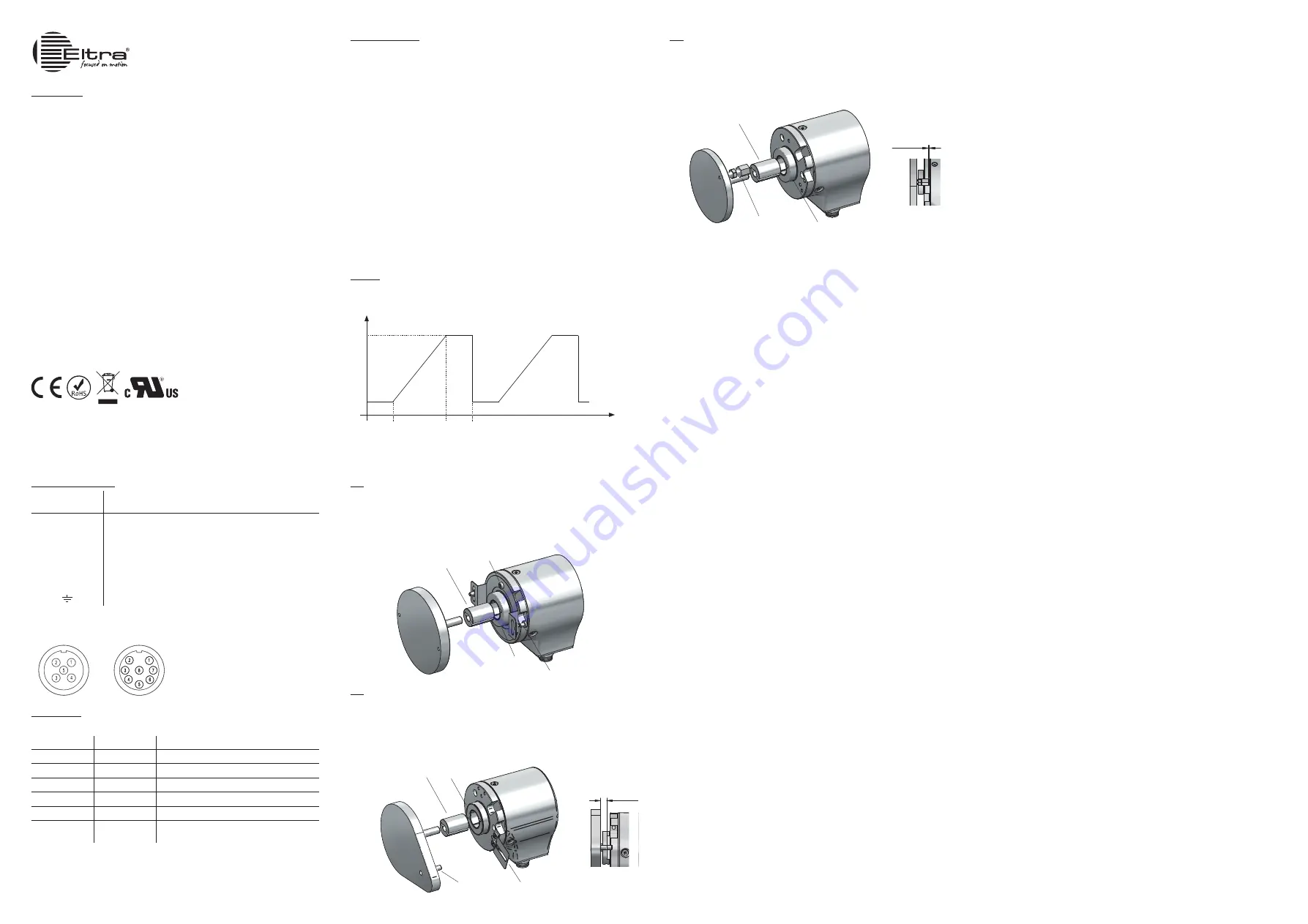

1. Apply the shaft adapter

1

(if present) to the encoder shaft and then to the customer motor shaft.

2. Apply the spring on the encoder with n.3 M3x4 supplied screws (recommeded threadlocker

Loctite 243), fi xing torque 0,4 Nm / 57 Ozin recommended.

3. Apply the encoder shaft on the motor shaft.

4. Fix the spring

2

to the customer motor fl ange without fi xing it with n.2 M3 screws

3

.

5. Fix the collar clamping

4

with an HEX key 2,5, fi xing torque 1,5 Nm / 212 Ozin recommended.

6. Fix the spring.

1. Apply the shaft adapter

1

(if present) to the encoder shaft.

2. Screw the torque pin

2

on the customer motor fl ange with key n.8, then secure it with the nut with key n.7.

3. Apply the encoder on the customer motor shaft, making sure the pin is inserted in the hole on the front

part of encoder, maintaining a minimum distance of 0,5 mm, see Figure A.

4. Fix the collar clamping

3

with an HEX key 2,5, fi xing torque 1,5 Nm / 212 Ozin recommended.

Figure A

1. Apply the shaft adapter

1

(if present) to the encoder shaft and then to the customer motor shaft.

2. Apply the bracket

2

on the encoder with n.3 M3x4 supplied screws (recommeded threadlocker Loctite 243),

fi xing torque 0,4 Nm / 57 Ozin recommended.

3. Apply the torque pin

3

to the customer motor shaft (recommeded threadlocker Loctite 243).

4. Apply the encoder shaft on the motor shaft and make sure to keep a minimum distance of 1 mm

between the bracket and the customer motor fl ange (fi gure A).

5. Fix the collar clamping

4

with an HEX key 2,5, fi xing torque 1,5 Nm / 212 Ozin recommended.

Figure A

Eltra S.p.a. Unipersonale

36040 Sarego - Italy tel. +39 0444 436489 fax. +39 0444 835335

www.eltra.it [email protected]

200610

63 G

cod.29050030

58 F

63 F

Min

Max

POS1

POS2

4

4

3**

1

2

3*

1

2

3

1

2