85

Uniform Stitch Adjustment

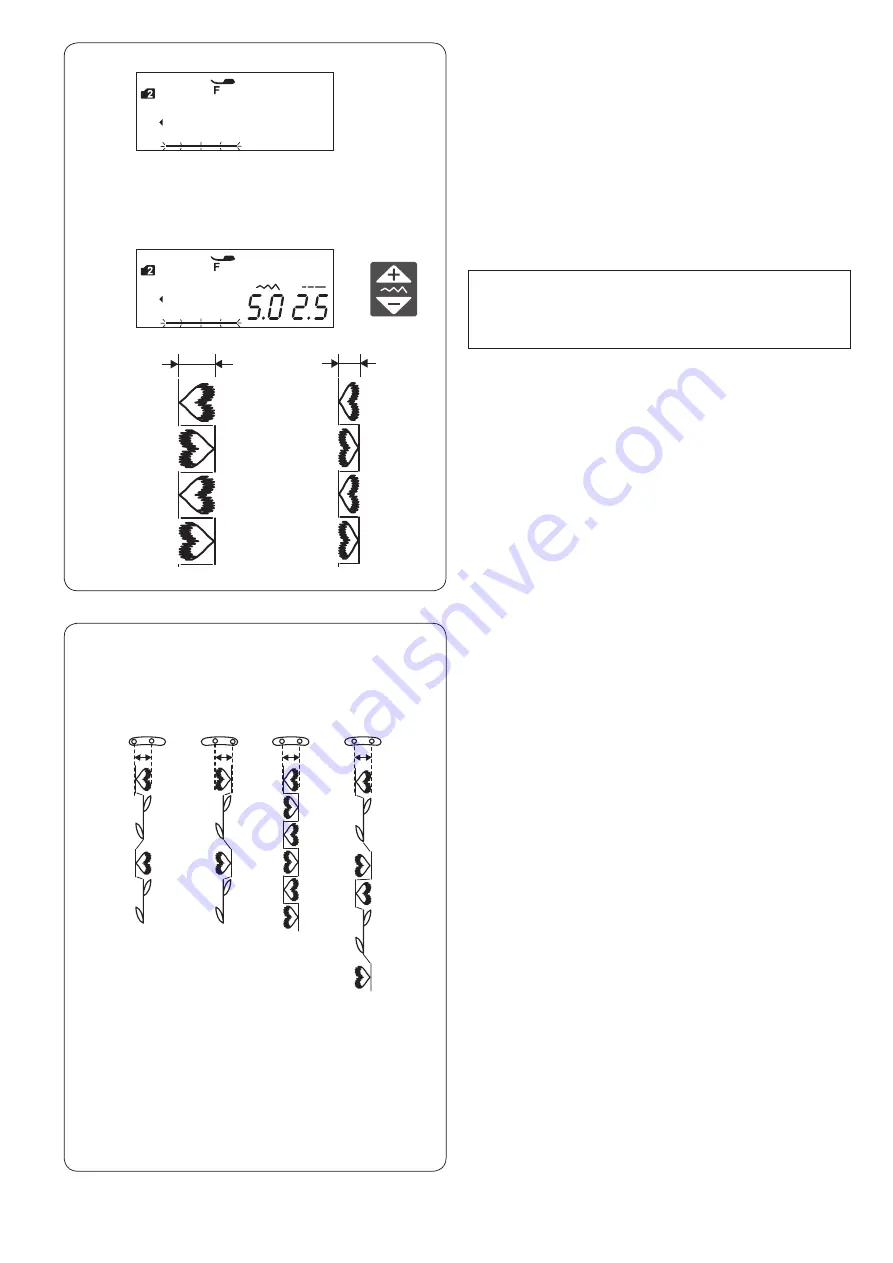

The stitch width and length of the programmed patterns

can be uniformly adjusted.

Example 1: Adjusting the stitch width of the programmed

pattern 52 (MODE 2) and its mirror image

Shift the cursor to the right of the last programmed

pattern.

Press the stitch width adjusting key to adjust the stitch

width.

NOTE:

Stitch length can be uniformly adjusted if the

programmed patterns in the same category (satin

stitches or stretch stitches) have been programmed.

The stitch width of the programmed patterns will be

adjusted uniformly.

q

Original width

w

Uniformly adjusted width

Unified Needle Drop Position

The needle drop position of the programmed patterns will

vary depending on the pattern combination:

(A) Unified to the left when combining the patterns with

the left needle position and the center needle

position.

(B) Unified to the right when combining the patterns with

the center needle position and the right needle

position.

(C) Unified to the center when combining the patterns

with the left needle position and the right needle

position.

(D) Unified to the center when combining the patterns

with the left, center and right needle positions.

q

w

(A)

(B)

(C)

(D)

Summary of Contents for eXcellence 730 PRO

Page 1: ...Instruction Manual eXcellence 730 PRO...

Page 2: ......

Page 95: ......

Page 96: ...858 850 028 EN...