3

9

D.1.3 MAINTENANCE INTERVALS

The inspection and maintenance intervals depend on the

actual machine operation conditions and ambient conditions

(presence of dust, damp, etc.), therefore precise time intervals

cannot be given. In any case, to minimise interruptions of the

service, careful and periodical machine maintenance is

advisable.

It is advisable to stipulate a preventive and scheduled

maintenance contract with the after-sales service.

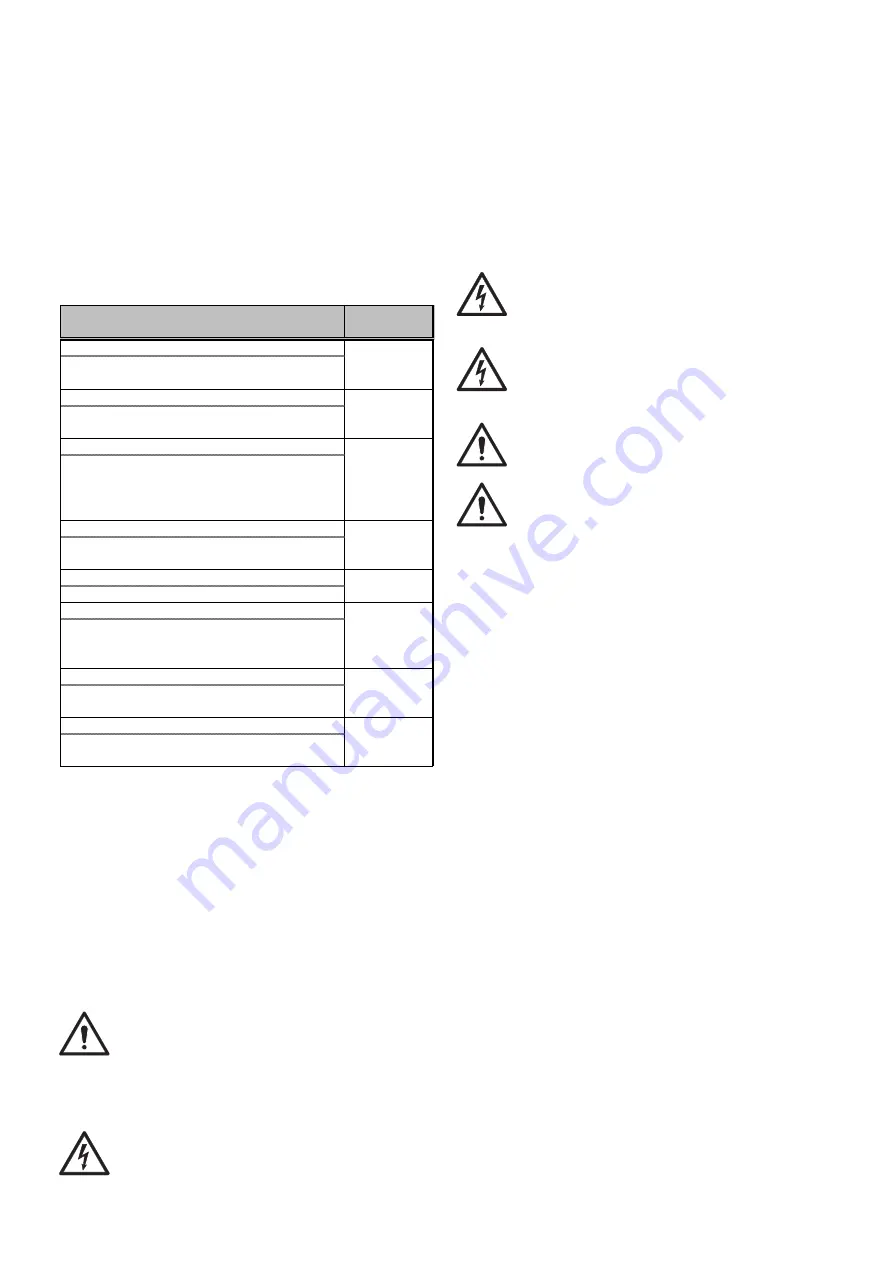

D.1.3.1 Maintenance frequency

In order to guarantee constant machine efficiency, it is advisable

to carry out the checks with the frequency given in the following

table:

MAINTENANCE, INSPECTIONS, CHECKS AND

CLEANING

FREQUENCY

Routine cleaning

General cleaning of machine and surrounding

area

Mechanical protection devices

Check condition, and for any deformation,

loosening or removed parts.

Control

Check mechanical part, for any breakage or

deformation, tightening of screws. Check

readability and condition of words, stickers and

symbols and restore if necessary.

Machine structure

Tightening of main bolts (screws, fixing systems,

etc.) of machine.

Safety signs

Check readability and condition of safety signs.

Electrical control panel

Check electrical components installed inside the

Electrical Control Panel

. Check wiring between

the Electrical Panel and machine parts.

Electrical connection cable and plug

Check connection cable (replace it if necessary)

and plug.

Extraordinary machine maintenance

Check all components, electrical equipment,

corrosion, pipes, ……

Every 10

years (*)

Daily

Monthly

Yearly

Yearly

Yearly

Yearly

Yearly

(*)

the machine is designed and built for a duration of about 10

years. After this period of time (from machine commissioning)

the machine must undergo a general inspection and overhaul.

Some examples of checks to be carried out are given below.

- check for any oxidised electrical components or parts; if

necessary, replace them and restore the initial conditions;

- check the structure and welded joints in particular;

- check and replace bolts and/or screws, also checking for any

loose components;

- check the electrical and electronic system;

- check the functionality of safety devices;

- check the general condition of protection devices and guards.

ATTENTION!

Machine maintenance, checking and overhaul

operations must only be carried out by a

specialised Technician or the After-Sales Service,

provided with adequate personal protection

equipment (safety shoes, gloves, glasses), tools

and ancillary means.

ATTENTION!

Work on the electrical equipment must only be

carried out by a qualified electrician or the After-

Sales Service.

D.1.4 DISASSEMBLY

If the appliance has to be disassembled and then reassembled,

make sure the various parts are assembled in the correct order

(if necessary mark them during disassembly).

Before disassembling the machine, make sure to carefully

check its physical condition, and in particular any parts of the

structure that can give or break. Before starting disassembly:

- remove all the pieces, if present, in the machine;

- disconnect the power supply;

- enclose the work area;

- place a sign on the Main Electrical Panel indicating that the

machine is undergoing maintenance and not to carry out

manoeuvres;

- carry out the disassembly operations.

ATTENTION!

All scrapping operations must occur with the

machine stopped and cold and the electrical power

supply disconnected.

ATTENTION!

Work on the electrical equipment must only be

carried out by a qualified electrician, with the

power supply disconnected.

ATTENTION!

To carry out these operations, appropriate PPE

must be used.

ATTENTION!

During disassembly and handling of the various

parts, the minimum height from the floor must be

maintained.

D.1.5 DECOMMISSIONING

If the machine cannot be repaired, carry out the decommissioning

operations, signalling the failure with a suitable sign, and

request assistance of the manufacturer’s after-sales service.