Electrolux air-o-steam - level A

Combi LW 20 GN 1/1-electric

Internet: http://www.electrolux.com/foodservice

EGA040

2010-04-13

Supply voltage

400 V, 3N, 50/60

400 V, 3N, 50/60

230 V, 3, 50/60

400 V, 3N, 50/60

Net weight - kg.

284

284

284

284

cooking chamber

34

34

34

34

electric

34.5

34.5

34.5

34.5

auxiliary

0.8

0.8

0.8

0.8

boiler

24

24

20

24

Power - kW

height

1450

1450

1450

1450

depth

715

715

715

715

width

460

460

460

460

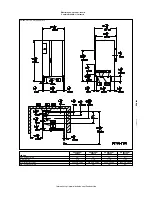

Internal dimensions - mm

height

1795

1795

1795

1795

depth

957

957

957

957

width

993

993

993

993

External dimensions - mm

N° of programs

100

100

100

100

Automatic cleaning system

●

●

●

●

Multi Point Probe

●

●

●

●

Two-speed fan

●

●

●

●

Low temp steaming

●

●

●

●

Regeneration

●

●

●

●

Cook&hold

●

●

●

Humidity control

●

●

●

●

Convection/steaming

●

●

●

●

Steaming

●

●

●

●

Convection

●

●

●

●

combi

250

250

250

250

steam

130

130

130

100

air-convection

300

300

300

300

Cooking cycles - °C

Runners pitch - mm

63

80

63

63

Number of grids

20

16

20

20

Power supply

Electric

Electric

Electric

Electric

TECHNICAL DATA

AOS201EAA1

267004

AOS201EAH1

267014

AOS201EAN1

267024

AOS201EAK1

267104

• air-o-clean: 4 different pre-set

cycles to clean the cooking cell,

according to the actual

requirements. The cleaning

system is built-in (no need for

add-ons).

• Quick cooling: useful when

passing to a type of cooking that

requires a lower temperature than

the previous one. It works

automatically and manually.

• Manual injection of water in the

cell.

• Automatic steam generator

water draining with an automatic

scale diagnosis system.

• HACCP management as

standard: it allows recording the

cooking programme according to

H.A.C.C.P. standard (Hazard

Analysis and Critical Control

Points). According to the system

requested it will be possible to

record the cooking data with the

oven’s printer (optional) or directly

in a Personal Computer (PC

network installation required).

PERFORMANCE

• air-o-clima: controls and

displays the exact (single degree

of accuracy) humidity degree of

the oven atmosphere in hot air,

combi and regeneration cycles.

Air-o-clima measures physically

the real humidity level inside the

cooking cell and acts

consequently according to the set

value. With hot air cycles,

air-o-clima also manages to

exhaust the excess humidity

generated by the food.

• air-o-flow: blows fresh air from

outside through the bi-functional

fan, which pulls the air in from the

backside of the oven after it is

pre-heated, thus guaranteeing an

even cooking process.

• Multi-sensor food probe: 6

sensors, ½ ºC accuracy.

CONSTRUCTION

• Stainless steel 304 throughout,

with seamless joints in the cooking

cell.

• Height adjustable legs.

• Double thermo-glazed door

equipped with drip pans to catch

condensate and prevent slippery

floor for maximum security and

four holding positions allowing

easier loading and unloading.

• Halogen lighting in the cooking

cell.

• Access to main components

from the front panel.

• Automatic scale diagnosis

system in the steam generator to

detect the presence of scale

build-up.

• IPX5 water protection.

• air-o-steam ovens meet IMQ

safety requirements.