3

CONTENTS

TECHNICAL SPECIFICATIONS

DIMENSIONS

Height

850 mm

Width

400 mm

Depth

600 mm

POWER SUPPLY VOLTAGE / FREQUENCY

230 V / 50 Hz

TOTAL POWER ABSORBED

2300 W (10 A)

HEATER RATING

1950 W

WATER PRESSURE

Minimum

5 N/cm²

Maximum

80 N/cm²

MAXIMUM RECOMMENDED LOAD Cotton, linen

5 kg

Synthetics,delicate fabrics

2,5 kg

Wool

1,0 kg

SPIN SPEED

800 rpm

This appliance complies with the following E.E.C. Directives:

- 73/23 EEC of 19.2.73 (Low Voltage Directive) and subsequent modifications;

- 89/336 EEC of 3.5.89 (Electromagnetic Compatibility Directive) and subsequent modifications.

Technical specifications ........................................................................................................................

Page

3

Warnings .................................................................................................................................................

Page

4

Installation ...............................................................................................................................................

Page

5

Unpacking ................................................................................................................................................. Page 5

Water connection ...................................................................................................................................... Page

5

Electrical connection ................................................................................................................................. Page

6

Levelling .................................................................................................................................................... Page 6

Use ............................................................................................................................................................

Page 7

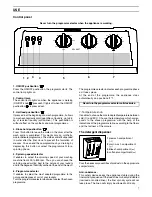

Control panel ............................................................................................................................................. Page

7

Washing hints ........................................................................................................................................... Pages 8-9

Wash programmes ................................................................................................................................... Page

10

Wash code symbols .................................................................................................................................. Page 10

Operating instructions ............................................................................................................................... Page

11

Maintenance ............................................................................................................................................

Page 12

Cleaning the machine ............................................................................................................................... Page

12

Cleaning the pump filter ............................................................................................................................ Page

12

Cleaning the detergent dispenser ............................................................................................................. Page

12

Something not working ? ......................................................................................................................

Page 13