23

I.6

Residual risks

The machine has several risks that were not completely

eliminated from a design standpoint or with the installation of

adequate protection devices. Nevertheless, through this

manual the Manufacturer has taken steps to inform operators

of such risks, carefully indicating the personal protection

equipment to be used by them. In order to reduce the risks,

provide for sufficient spaces while installing the unit. To

preserve these conditions, the areas around the machine

must always be:

• kept free of obstacles (e.g. ladders, tools, containers, boxes,

etc.);

• clean and dry;

• well lit.

For the Customer's complete information, the residual risks

remaining on the machine are indicated below: such situations

are deemed improper and therefore strictly forbidden.

Residual risk

Description of hazardous

situation

Slipping or falling

The operator can slip due to water

or dirt on the floor

Catching, dragging or

crushing

Catching or dragging of the oper-

ator or other persons in the drive,

during the machine work phase,

due to improper actions, such as:

• placing an arm inside the

machine to remove a stuck rack

without stopping the machine

by operating an emergency

switch;

• accessing the rack handling

system without stopping the

machine by operating an emer-

gency switch.

Use of improper clothing with

loose parts (e.g. necklaces,

scarves, shawls, ties, etc.) or long

hair not gathered, which could get

caught up in moving parts.

Burns/abrasions (e.g.

heating elements,

cold pan, cooling cir-

cuit plates and pipes)

The operator deliberately or unin-

tentionally touches some

components inside the machine

without using protective gloves.

Stab wounds

The operator deliberately or unin-

tentionally touches some

components with sharp edges

during the machine cleaning with-

out using protective gloves.

Residual risk

Description of hazardous

situation

Burns

The operator deliberately or unin-

tentionally touches some

components inside the machine or

dishes at the outfeed without using

gloves or without allowing them to

cool.

Shearing of upper

limbs

The operator violently closes the

front panels.

Electrocution

Contact with live parts during

maintenance operations carried

out with the electrical panel

powered

Falling from above

The operator intervenes on the

machine using unsuitable systems

to access the upper part (e.g. rung

ladders, or climbs on it)

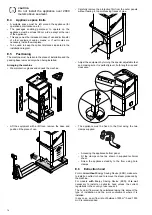

Crushing or injury

The specialised personnel may

not correctly fix the control panel

when accessing the technical

compartment. The panel could

close suddenly.

Crushing or shearing

Possible risk of injury to upper

limbs during the hood closing

operation.

Tipping of loads

When handling the machine or the

packing containing it, using unsuit-

able lifting systems or accessories

or with the unbalanced load

Chemical

Contact with chemical substances

(e.g. detergent, rinse aid, scale

remover, etc.) without taking

adequate safety precautions.

Therefore always refer to the

safety cards and labels on the

products used.

IMPORTANT

In case of a significant anomaly (e.g. short circuits,

wires coming out of the terminal block, motor

breakdowns, worn electrical cable sheathing, etc.)

the operator must immediately deactivate the

machine.

J

NORMAL MACHINE USE

J.1

Foreseen use

Our appliances are designed and optimised to ensure high

performance and efficiency. This equipment must only be used

for its expressly designed purpose, i. e. washing dishes with

water and specific detergents. Any other use is deemed

improper.

This appliance does not carry out the rinse cycle should there

be no supply water; it stops all functions with an error message

“A1“ (also see Alarms).

J.2

Operator qualified for normal machine

use

Must have at least:

• knowledge of the technology and specific experience in

operating the machine;

• adequate general basic education and technical knowledge

for reading and understanding the contents of the manual,

including correct interpretation of the drawings, signs and

pictograms;

• sufficient technical knowledge for safely performing his

duties as specified in the manual;

• knowledge of the regulations on work hygiene and safety.

In case of a significant anomaly (e. g. short circuits, wires

coming out of the terminal block, motor breakdowns, worn

electrical cable sheathing, etc.) the operator for normal

machine use must:

• immediately deactivate the machine by turning the switch

disconnector to “O“ or operating the main emergency switch

on the equipment;

• close the machine water supply by shutting off the water.