indeed set back to factory settings. Do this by re-

entering the calibration procedure. If the 4 mA to 20

mA output signal is at 12 mA (or fairly close) when in

the calibration mode, then you have properly restored

R7 and R8 settings.

D) Continue and complete the calibration procedure for

the process’s fully-closed and fully-open positions.

How to clear-out the existing calibration, and

reprogram the SG1000 (Two methods)

One, 24Vdc power, then press and hold-in the SW2

button while re-applying the +24Vdc power to the SG1000.

Continue to keep the SW2 button pressed-in for a few seconds

until the SG1000 outputs 12 mA, then release the SW2 button.

The old calibration has now been cleared-out, and the SG1000 is

in calibration mode awaiting new calibration.

Or two, while powered, press and hold-in the SW2 button for 5

to 6 seconds to enter calibration mode.

See the “

Calibration Procedure

” section for complete details.

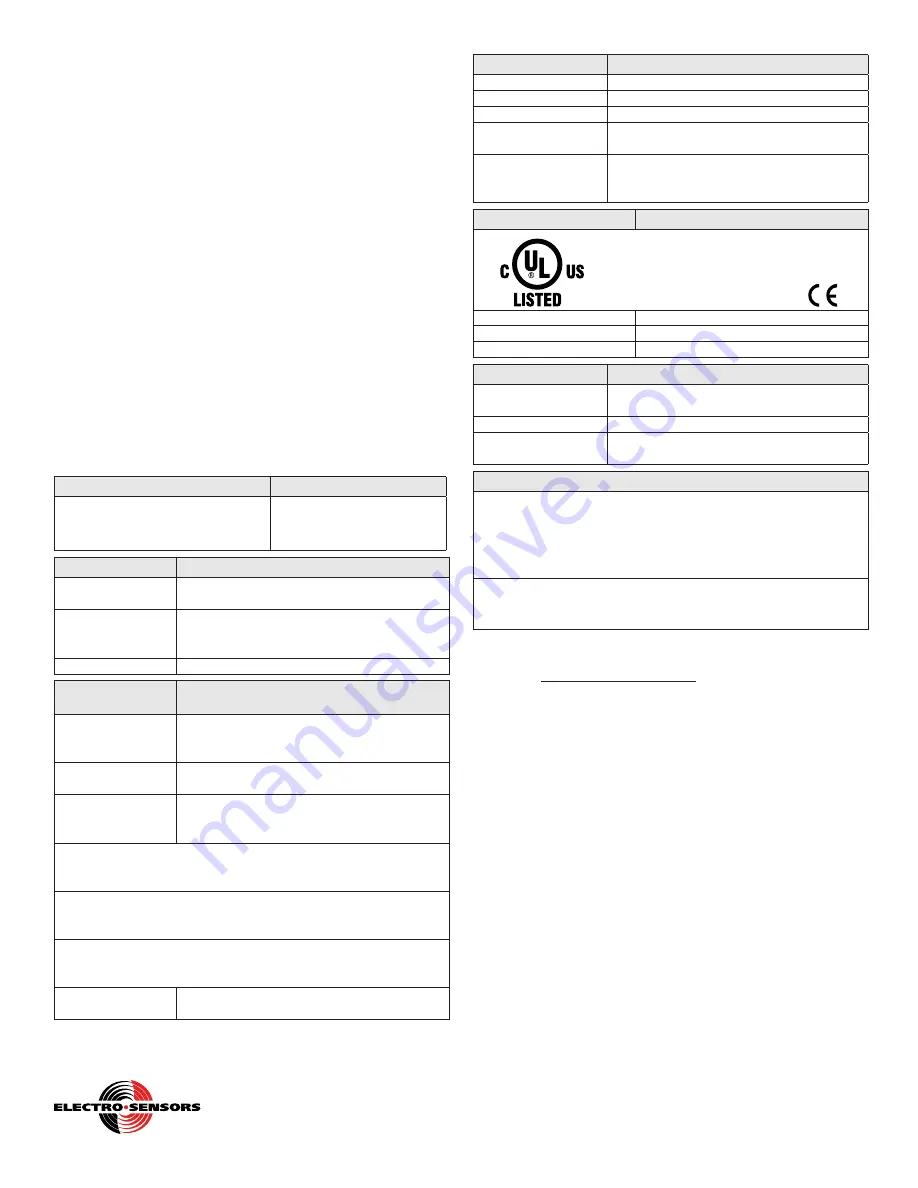

SG1000E General Specifications:

Input Power

Input Current

REQUIRES USER INSTALLED

CLASS 2 ISOLATED

+24 VDC ±10% Power Supply

40mA max (when output

signal is at 20mA)

Input Signal

Parameters

Type

Rotating shaft connected to internal 9 bit, 0 to

511 count, absolute position encoder

Range of Operation

Continuous rotation with no physical end stops.

Calibratible span of 5.6º turn to 130º turn of

output shaft.

Internal Gear Ratio

1:2.75

Analog Output

Signal

Parameters

Type

4-20 mA DC, with programmable end-points:

(4 mA @ user’s fully closed position)

(20 mA @ user’s fully open position)

Accuracy

Resolve to 1 encoder count of calibrated span

position (span from fully closed to fully open).

4-20 mA

Resolution

Varies linearly from best of 0.2% of span,

to worst of 5.0% of span

depending on calibration

0.2% resolution occurs when calibrated at the maximum span of

511 encoder counts, which is a 130º turn of the output shaft. That

is, 1 count out of 511 counts is about 0.002, or 0.2 %

5.0% resolution occurs when calibrated at the minimum span of 21

encoder counts, which is a 5.6º turn of the output shaft. That is, 1

count out of 21 counts is about 0.05, or 5 %

Since the 4-20 mA output has a 16 mA span, a 0.2% resolution

gives an incremental change of 0.032 mA, and a 5.0% resolution

gives an incremental change of 0.800 mA.

Required

impedance

4-20 mA output needs a 250 to 500 Ω load

Mechanical

Parameters

Mounting

End of Shaft, single drilled and tapped hole.

Mounting Threads

3/8-16 UNC x 0.625 in.

Housing Material

Cast Aluminum

Housing Dimensions

Cylindrical, with diameter of 3-11/16”, length

of 7-5/8” (length includes housing & shaft)

Stabilizer Bracket

Mounted semi-rigidly to application’s

framework using two user supplied 5/16”

bolts.

Physical/Enviroment

Parameters

Class I, Groups C, D

Class II, Groups E, F, G

UL File: E249019

Additional Rating

NEMA 4X, Gasket Provided

Temperature Range

-40ºC to +65ºC (-40ºF to +149ºF)

Humidity

0% to 90% non-condensing

Operator Interface

Parameters

One Pushbutton

Enter calibration mode and calibrate for fully

closed/fully open process shaft positions

One Slide Switch

Select calibration direction CW/CCW

Memory

EEPROM retains calibration during power

failure or power shut down

Operation Modes

Normal Operating Mode:

(output signal per process shaft position)

.

- Output: 4 mA to 20 mA signal proportional to process shaft

position, for a properly calibrated SG1000.

- Output: Constant 12 mA for an uncalibrated or miscalibrated

SG1000.

Calibration Mode:

(select calibration direction, calibrate for fully-

closed / fully-open process shaft positions)

.

- Output: Holds at a constant 12 mA in this mode.

Additional Information

To get additional information about the SG1000E, visit our

website at: www.electro-sensors.com

Notice:

Copyright © 2016 Electro-Sensors, Inc. All rights reserved. No part

of this document can be duplicated or distributed without the express

written permission of Electro-Sensors, Inc.

While the information in this manual has been carefully reviewed for

accuracy, Electro-Sensors, Inc. assumes no liability for any errors or

omissions in the information. Electro-Sensors, Inc. reserves the right

to make changes without further notice to any part of this manual or

product described in this manual.

4-4

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-002440 Revision D