Operating instructions

9

MAINTENANCE

Warning

!

- electrical tension

Even if the machine is switched off, there will still

be current in some of the circuits, and electric

shocks can cause injury if work is being done on

them. The master switch must be switched off or

the plug pulled out of the mains socket before any

maintenance work is done.

Warning

!

- air pressure in the machine

Even if the machine is switched off, the air in the

pipes can still be under pressure, and the

unexpected escape of compressed air can cause

injury if work is being done on them. Pressure must

always be let off from the machine before any

maintenance work is done.

LETTING AIR OFF FROM THE MACHINE

•

The compressor block releases its air pressure

automatically if the plant is switched off in the

proper way (see “Starting up and operating”).

•

To deaerate the air receiver open the

condensate drain and let the total pressure off.

TO DRAIN THE AIR RECEIVER OF

CONDENSATE

On units with air receiver open the condesate drain

„under pressure“ until pure compressed air issues.

Then close the drain again. Condensate contains

oil and must therefore be disposed of in an

environmentally responsible way.

CHECK THE OIL LEVEL

CAUTION!

Condensation can ruin the machine

completely

If the machine is set up in a cool, damp place, such

as in a cellar, condensation can form in the

lubricating oil. This is particularly likely to happen if

the compressor is run for too short a time and thus

does not reach its full operating temperature. This

condensation then reduces the lubricating effect on

pistons and bearings, and that could destroy them

completely. The signs of condensation in the

lubricating oil are an excessively high oil level, a

milky colour in the oil, or drops of water in the

inspection window. If any of these occur, the oil

must be changed at once.

Remedy: install the compressor in a warm, dry

room, or use a smaller compressor.

•

Check the oil level weekly, and top up with an

appropriate oil if necessary.

•

Never mix oil of different types or quality grades

together.

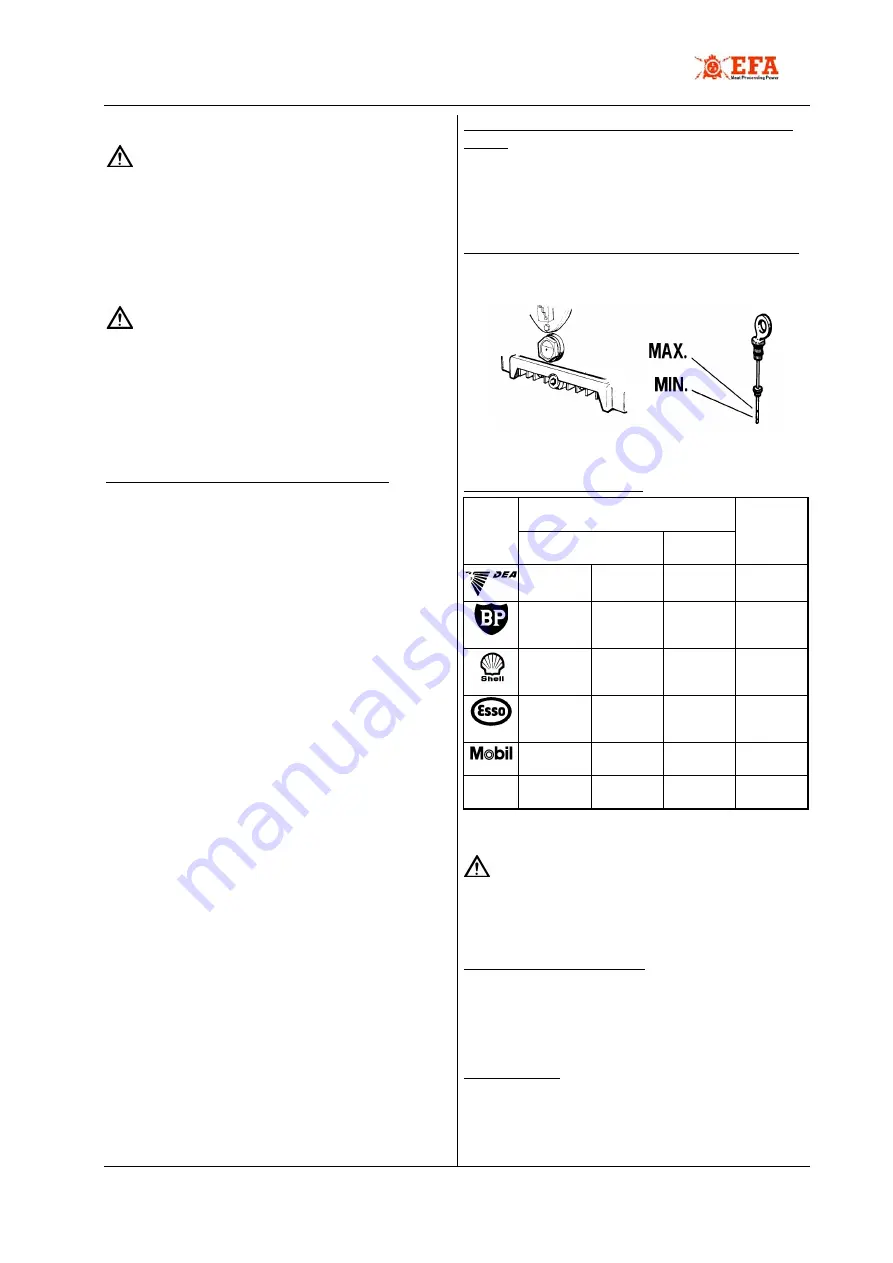

OIL-LEVEL CONTROL ON UNITS WITH OIL DIP

STICK

⇒

Extract oil dip stick

•

The oil level must be between the notches on

the oil dip stick

OIL-LEVEL CONTROL ON UNITS WITH OIL-EYE

⇒

The oil level shown in the oil-eye must be within

the circle.

A.)

Oil -eye

B.) Oil dip stick

SUITABLE TYPES OF OIL

Mineral

oils

Synthetic

oils

Single-grade

oil

Multi-grade

oil

Actro EP

VDL 150

Actro EP

VDL 100

Regis SAE

20W-20

Xenic EP

VDL 100

BP Energol

RC 150

BP Energol

RC 100

BP Energol

HD-S SAE

20 W 20

BP Energol

RC-S100

Shell

Corena Öl

H150D

Shell

Corena Öl

H100D

Shell Rotella

X 20 W 20

V-Öl 7010

Compressor

oil 3022 N

Compressor

oil 3021 N

Essolube

HDX

Plus + 30

Mobil Rarus

429

Mobil Rarus

427

Mobil Rarus

829

Mobil Rarus

827

Liqui

Moly

LM

500

OIL CHANGE

Warning

!

- hot oil

Compressor oil can be very hot, and there is a

danger of being scalded. Take all necessary care

with this work.

OIL-CHANGE INTERVALS

•

Mineral oil: every 500 operating hours

•

Synthetic oil: every 1,000 operating hours

•

Carry out an oil change at least once a year.

PROCEDURE

⇒

Oil quantity: see technical data.

⇒

Let off the used oil at normal operating

temperature.

⇒

Close the oil outlet screw.

Summary of Contents for 001 606 885

Page 1: ...Betriebsanleitung 2 Operation manual VB 125 235 Type VB 125 to 235 PISTON COMPRESSORS...

Page 3: ...Betriebsanleitung 4 EFA 6 EFA...

Page 4: ...Betriebsanleitung 5...

Page 5: ...Betriebsanleitung 6 40 5 C 40 C 10 10 3...

Page 6: ...Betriebsanleitung 7 0 0 1...

Page 7: ...Betriebsanleitung 8 0 15 20...

Page 9: ...Betriebsanleitung 10 500 100 M 8 25 M 10 50 M 12 85...

Page 23: ...Schmid Wezel D 75433 Maulbronn Page 13 15 Version 09 2008 A 4...

Page 24: ...Schmid Wezel D 75433 Maulbronn Page 14 15 Version 09 2008 A 5 Installation plan 200 2000...