1

BL 9228 / 06.12.07 e

Power Electronics

•

According to IEC/EN 60 947-4-2, prEN 1870-1, GS-HO-01

•

2-phase motor control

•

For motors up to 15 kW bei 3 AC 400 V

•

Separate settings for start and brake time, as well as starting

and braking torque

•

Control input and relay output for emergency stop according to

safety category 1, EN 954-1

•

No braking contactor necessary

•

With automatic standstill detection

•

This brake system fullfills the requirements of category 2

according to EN 954-1 of "Recommandation for Use"

(CNB/M/01.051IR/E), prEN 1870-1, GS-HO-01

•

Safe separation of the motor from the mains after fault or

brakefunction via external contactor, category 1 according to

EN 954-1

•

Maintenance- and wearfree

•

Auxiliary voltages 230 V and 400 V

•

Monitors undervoltage and phase sequence

•

3 relay outputs for indicaiton of status and fault with LED-indication

•

With input to detect motor temperature

•

BL 9228 up to 7.5 kW: 90 mm width

BL 9228 up to 15 kW: 112.5 mm width

Softstarter with DC-Brake BL 9228

ministart

All technical data in this list relate to the state at the moment of edition. We reserve the right

for technical improvements and changes at any time.

A 0249781

Approvals and marking

Applications

•

Motor with gear, belt or chain drive

•

Fans, pumps, conveyor systems, compressors

•

Woodworking machines, centrifuges

•

Packing machines, door-drives

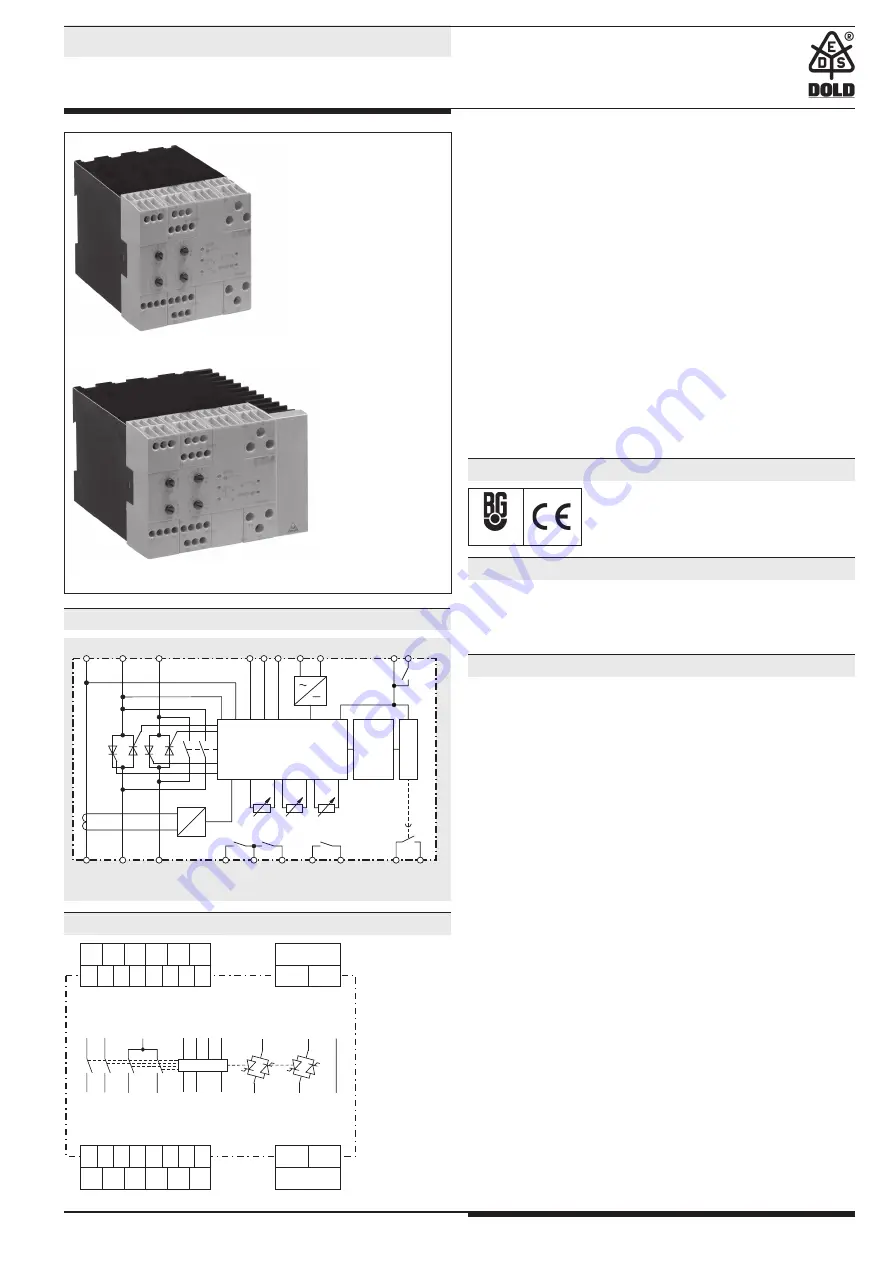

Block diagram

BL 9228 up to 15 kW

BL 9228 up to 7.5 kW

L1

L2

L3

A1

P1 P2 P3

A2

X1 X2

T1

T2

T3

M5667

M on

electronics

supply

t on

I Br

micro control

safety

monitoring

33

34

Tv

14

43

13

44

24

I

U

HBG

Circuit diagram

M8464_c

33

34

P1

P2

P3

13

A1

X1

24

A2

X2

L1

T1

L3

T3

14

43

44

L2

T2

L2

33

43

34

44

A1

T2

L3

L1

T3

T1

X1 X2 P1 P2

A2

P3

13

24

14

Softstarters are electronic devices designed to enable 1-phase or

3-phase induction motors to start smoothly. The devices slowly

ramps up the current on two phases, therefore allowing the motor

torque to build up slowly. This reduces the mechanical stress on the

machine and prevents damage to conveyed material.

These features allow cost saving constructions of mechanical gear.

A special monitoring allows the application in systems of safety

category 2.

Start/Stop switch

When the motor is on full speed after the starting with start switch the

semiconductors are bridged with internal relay contacts to prevent

internal power losses and heat built up.

When stopping the motor via start switch braking is started. The

braking current flows until detection of the stillstand through the motor

windings. If the brake function takes longer than 10 sec, the monitoring

relay 1 provides a signal. After 15 sec the brake function will be finished

and the motor will be separated from the mains via contactor K1.

Monitoring relay 1 (contact 13-14)

Relay 1 is energised if the brake function takes longer than 10 sec. By

restarting of the device this relay is de-energised. However, if the

brake function has been longer than 10 sec for the third time, the device

is set into an error mode. The red LED flashes code 9. This fault can

only be reset by switching on and off the power supply.

Monitoring relay 2 (contact 13-24)

This relay energises as soon as the unit is ready for operation after

connecting it to power. If any error occurs the monitoring relay 2 will

be de-energised immediately. The power output will be switched off.

Monitoring relay 3 (contact 33-34)

The relay is energised after activating the on-button and is de-

energised after indication of the motor standstill at the end of braking.

If standstill is not detected, the relay is de-energised after pushing the

off-button and elapse of a safety time. The relay is operating the motor

contactor. It is immediately de-energised by any fault indication.

Function