time the machine is used. Failure to do that may cre-

ate a flood around the machine.

• Do not leave dirty water inside the tank, pump or hos-

es after each operation of the machine. Run clean wa-

ter through the pump. Rinse the tank and completely

drain the vacuum and discharge hoses. Run vacuum

motor for three minutes minimum so that the inside

of the vacuum turbine is free of residual moisture.

• Monitor vacuum system to prevent flooding.

GROUNDING INSTRUCTIONS:

This piece of equipment must be grounded. Should an

electrical malfunction occur, grounding provides a path

of least resistance for electrical current, reducing the risk

of electric shock. This piece of equipment is furnished

with a cord that has a grounding conductor and ground-

ing plug. The grounded plug must only be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordi-

nances.

WARNING:

Connecting the equipment to an improperly grounded

outlet can result in an increased risk of electric shock. A

qualified electrician should be consulted if you are un-

sure that the outlet is properly grounded. Do not modify

the plug provided with the equipment. If it will not fit

the outlet, have a proper outlet installed by a qualified

electrician.

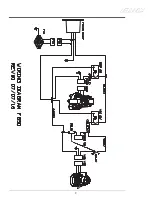

This appliance is designed for use on a 120-volt circuit.

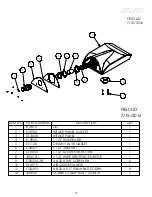

The grounding plug provided looks like the plug illus-

trated in Figure 1. Replace the power cord if the ground-

ing pin is damaged or broken.

Extension cords connected to this machine should be

12 gauge, three-wire cords with three-prong plugs and

outlets. DO NOT use extension cords more than 25 feet

(7.6 m) long.

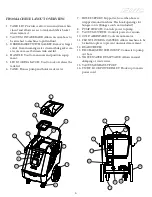

DAILY MAINTENANCE:

The FLOODBUSTER FB50 is engineered and built to

require minimum maintenance. But like any machine,

it does require some care to keep it in optimum work-

ing condition. Careful attention to these maintenance

instructions will give you maximum operating perfor-

mance and life expectancy of the machine.

CAUTION: Disconnect the power cord from the out-

let before doing any clean up or maintenance on the

machine

1. Keep the equipment and accessories, inside and out,

clean and dry including lid, filter strainer, waste tank,

hoses.

2. Vacuum motor: It is very important that the vacuum

motor is internally free of moisture when not used.

Run the vacuum motor with the lid and hose off for

3 minutes after every operation.

3. Pump motor: Periodically hose off the surface of the

pump so that no debris may remain on the surface

and opening of the pump. Such debris may cause

pump damage in time.

Servicing:

In the event that your equipment requires service, please

contact EDIC at:

800-338-3342

or email [email protected]

Do not attempt repairs yourself. EDIC will assist you in

locating an indepedent service contractor.

Storage:

1. Store in a clean, dry location.

2. Store with the lid off the machine

Purchase record:

Fill in the blanks and keep for future reference.

Model #:

Serial #:

Distributor name:

Distributor contact:

4

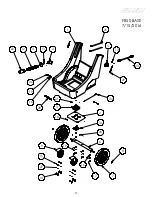

Figure 1

Summary of Contents for FLOODBUSTER FB50

Page 10: ...9...