44

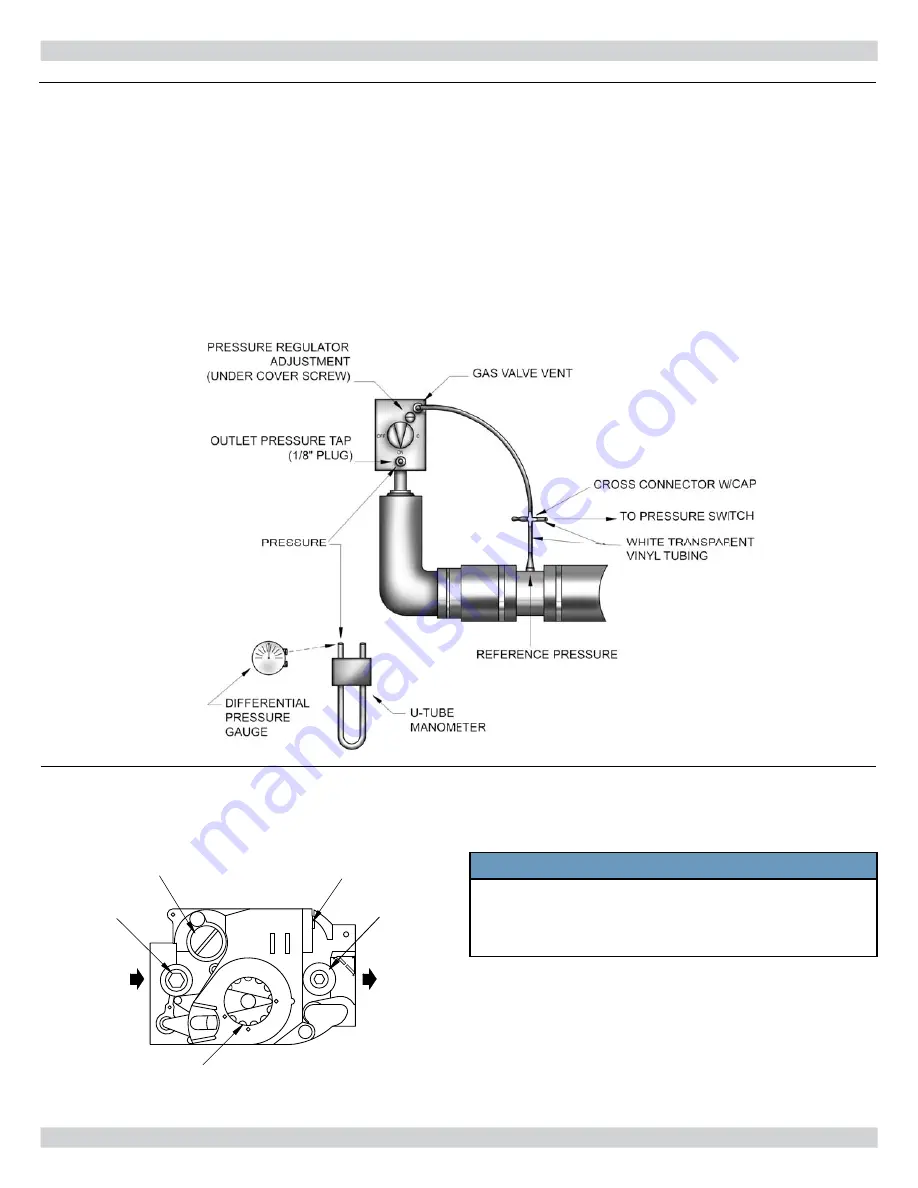

Following steps and diagram indicate location of the

connection points required to measure manifold pressure.

Manifold pressure may be measured using a U-Tube

Manometer or Differential Pressure Gauge. Diagram shows

connection of both measuring devices. Only ONE DEVICE IS

REQUIRED to measure manifold pressure.

Remove plug. Install appropriate barbed

fi

tting and connect

pressure side line from U-Tube Manometer or Differential

Pressure Gauge.

OFF

ON

INLET

OUTLET

GAS CONTROL KNOB

PRESSURE REGULATOR

ADJUSTMENT (UNDER CAP SCREW)

INLET

PRESSURE

TAP

VR8205

WIRING TERMINALS (2)

OUTLET

PRESSURE

TAP

Figure 25 - Manifold Pressure Measurement Detail

Figure 26 - Gas Valve

VERIFICATION PROCEDURE AND ADJUSTMENT

Refer to “Differential Air Pressure Switch Check - all

models” on page 45 when reading manifold pressure.

When measurement is complete, disconnect U-Tube

Manometer or Differential Pressure Gauge. Be sure to

reinstall

⅛

” plug, using appropriate pipe thread sealant

approved for use with natural and lique

fi

ed Petroleum

gases.

NOTICE

Regulator cover screw must be installed at all times

unless adjusting manifold pressure. Firing rate and

manifold pressure must only be measured with cover

screw

fi

rmly installed.

Summary of Contents for Dunkirk 4 Series

Page 33: ...33 Figure 22 Ladder Diagram for Figure 22 ELECTRICAL WIRING ...

Page 52: ...52 Troubleshooting Chart 1 TROUBLESHOOTING ...

Page 53: ...53 Troubleshooting Chart 2 TROUBLESHOOTING ...

Page 63: ...NOTES ...

Page 64: ...DUNKIRK BOILERS 2201 Dwyer Avenue Utica NY 13501 web site www ecrinternational com ...